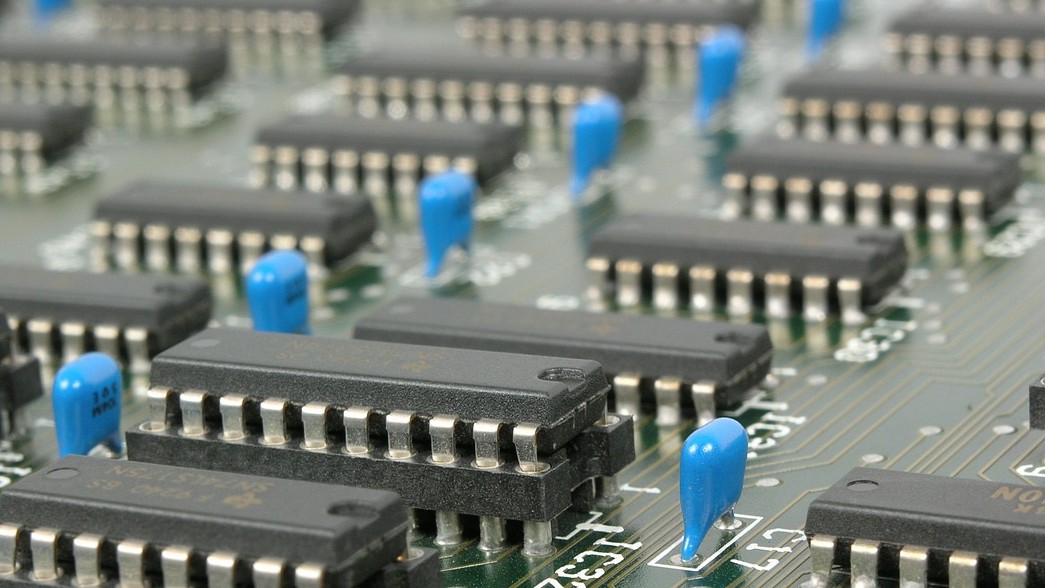

Flexible open frame panel PCs are built from ground up to be easily integrated into custom solutions. The open frame means a device is mainly placed in a metal enclosure and does not have a bezel. Instead, it is typically shipped with various mounting options or options that allow it to be easily integrated or embedded into the existing ecosystem. Electronic components such as display controller, harnessing, or internal power supply in the flexible open frame panel PCs are fastened to the inside of the robust metal chassis.

Advantages of Flexible Open Frame Panel PCs

Open frame panel PCs offer unprecedented flexibility due to their design. It allows them to be configured for many applications and integrated into any custom product design using its mounting system. A powerful combination of an industrial-grade display and an industrial-grade PC creates a robust all-in-one fully integrated solution.

Flexible open frame panels PCs significantly simplify installation. They remove the need for additional cabling, or multiple mounting points for various peripherals and components (as opposed to the case with the mouse and keyboard PCs with back-end computer to conceal).

The open frame panel PCs are specifically designed for those cases when a customer wishes to integrate them into an existing system and customize it, for example, with a branded front bezel, or uses as an embedded computer.

Additionally, the majority of industrial grade panel PCs can be panel mounted, which means the front of the unit needs to be protected and withstand harsh industrial environments such as temperature, humidity, and can be washed. Units that need to be VESA-mounted have an all round solid and liquid ingress protection, perfect for rugged industrial environments.

Market Segments and Applications

Industrial flexible open frame panel PCs are widely used in a large variety of applications across numerous commercial and industrial market segments:

- Point-of-sale terminals in restaurants and retail stores

- Food and processing industry in production floors with high temperatures, humidity and often grease

- Digital signage in wholesale warehouses, supermarkets, train stations, departments stores, in logistics

- Medical imaging

- Fitness and sports solutions

- Information Kiosk for hotels, hospitals, libraries

- Self-serve Kiosk for airports, supermarkets, movie rentals, ATM terminals for self-ticketing or self-checkout purposes

- Avionics applications

- Vending and gaming machines

- Machine control

- Process control

- Industrial manufacturing

- Human Machine Interface use cases in industrial automation for industrial communication protocols that allow users to monitor and control automated processes

- With the advent of Technology 4.0 and IoT, many industries are adding the connectivity features to their legacy equipment through embedded systems

… and many other use cases.

Important Features of Flexible Open Frame Panel PCs

- Industrial open frame panel PCs must be designed to withstand harsh manufacturing conditions. They must be dust and moisture-proof, and be easy to clean.

- They must be manufactured and assembled using military-grade, high-quality components to ensure the long MTBF of discreet parts, long product life cycle of 5+ years, and feature a low overall failure rate of less than 2%.

- Of note: the overall failure rate, product life cycle, and MTBF must be accounted for based on the 24/7 use of the computers, which is their regular industrial work cycle.

- A fanless design is not only about the reduction of noise, but also about increasing the durability of the PC, since a fanless PC has less moving parts prone to failure. The passive cooling system in fanless PCs also means significantly lower power consumption, which in its turn means cost reduction.

- Industrial-grade components must be high voltage to endure extreme industrial conditions.

- The touchscreen technology must be industrial-grade, with antiglare coating for flawless imaging in any lighting conditions, and when viewed from any angle.

- The industrial open frame panel PC must be highly customizable to meet your specific demands and needs. If a base configuration features any certificates, inquire whether your custom configuration will have these certifications, too. Mounting options like platform or VESA must be customizable. You must be able to choose the memory, processor, and other options.

- Of special note is the availability of serial ports that would allow for the integration of the open frame panel PC into an ecosystem with legacy external devices and peripherals.

- Some environments call for ingress protection with all round solid and liquid ingress protection, and waterproof I/O connectors. The IP64 certification reduces the maintenance costs, extends the life of the PC and averts mechanical failures.

- Open frame panel PCs apt for industrial use must withstand variable temperatures – look for the temperature rating of up to 70°C / 158°F.

- In industrial environments, a panel PC must have a resistive touch technology to allow users wear gloves while using it. Some environments call for stylus support.

The end product must be easily integrated into any industrial system with the aesthetics and functionality meeting rugged design, ease of use and affordability, as well as low maintenance costs and the overall TCO.

Industrial environments everywhere are harnessing the benefits of flexible open frame panel PCs, which allow them to connect the legacy and new equipment and form a connected, smart environment. The flexible open frame panel form factor has an immense application and an even bigger potential with the advent of the Technology 4.0.

The Definition of Open Frame Panel PC and Its Advantages

July 17, 2017

An open frame panel PC incorporates a touchscreen display into the same enclosure as its internal components such as the processor, hard drive or solid state drive, motherboard, I/O ports and the power supply. Such…

0 Comments10 Minutes

Why Panel PCs Play an Important Role in an Industrial Environment

July 16, 2015

Professionals from different industries have come to rely on electronic devices like computers to carry out a variety of tasks. Some industries require the use of specialized devices to meet the demands of a rigorous…

0 Comments4 Minutes

Types of Industrial PCs Used in Industrial Automation

February 10, 2017

The industrial sector is increasingly experiencing the impact of the Industry 4.0 concept. Whether you are looking to optimize the workflow, increase production or savings in maintenance, or explore new automation…

0 Comments8 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox