Passive cooling is a robust solution for maintaining optimal operating temperatures in computing devices. In today’s tech-driven world, passive cooling plays a critical role in various industries, from medical facilities demanding constant cleanliness to industrial environments facing dust and grime.

In this article, we’ll delve into the inner workings of passive cooling, its benefits, and its applications in arenas where silence, reliability, and environmental challenges are paramount.

Understanding Passive Cooling

Article Guide

For a computer to operate without overheating, it must manage two primary heat sources: the environment’s temperature and the computer itself.

First, it’s harder for a computer to maintain an optimal temperature in extremely cold or hot environments. This means extra care is required when the device operates outside a comfortable temperature range.

The second most common source of heat is the computer itself. The energy powering the processor generates heat, and design inefficiencies can lead to temperature spikes.

Computers can briefly withstand temperatures of up to 150 degrees Fahrenheit (70 degrees Celsius) without permanent damage. However, sustained exposure to these high temperatures can lead to shutdowns and failures.

The consequences of overheating are often underestimated:

- Increased heat can reduce the electrical resistance of components, leading to more electricity flow and a vicious cycle of overheating.

- Batteries can suffer shortened life spans or even fail due to accelerated chemical reactions caused by heat.

- Precise components like hard drives can experience damage, resulting in data loss.

- In extreme heat, components soldered onto the motherboard may melt or fall off, causing catastrophic failures.

Active vs. Passive Cooling

The primary goal of any computer’s cooling system is to maintain an optimal temperature. Traditional cooling methods typically involve fans that circulate air to dissipate heat. However, fan-based cooling systems have some notable drawbacks.

Fans can be noisy, and their noise levels tend to increase as the computer gets hotter, often causing disruptions. Furthermore, devices with fans cannot be fully sealed, limiting their applications in water-resistant and dustproof environments. Additionally, the presence of moving parts, like fans, can lead to malfunctions.

In contrast, passive or fanless cooling systems offer a quieter, more reliable, and versatile solution.

| Aspect | Active Cooling | Passive Cooling |

|---|---|---|

| Noise Level | Can be noisy, especially under heavy load. | Offers quieter operation, ideal for noise-sensitive environments. |

| Sealing Possibility | Requires airflow and can't be fully sealed. | Can be fully sealed, making it suitable for water-resistant and dustproof applications. |

| Reliability | The presence of moving parts, like fans, may lead to malfunctions over time. | Fewer moving parts improve reliability. |

| Space Efficiency | Generally simpler and takes up less space. | More complex and may require more space. |

How Does Passive Cooling Work

Passive cooling employs various methods to regulate a computer’s temperature without fans. Some common techniques include heat sinks, pipes, peltier modules, or vapor chambers designed to absorb and dissipate heat efficiently.

Heat sinks, the most frequently used method, absorb and transfer heat from hot components through thermally conductive materials, effectively stabilizing the computer’s temperature.

Advantages of Passive Cooling

There are several advantages to fanless cooling computers, including improved durability, enhanced resilience and quieter operation.

Improved Durability

Fanless cooling computers are known for their superior durability. Unlike devices with fans, which are prone to malfunctioning, fanless systems offer a more rugged solution. Dust buildup is a common issue with fans, causing components to clog and cease functioning.

Additionally, fans can easily break or become loose when the device is dropped or bumped, leading to overheating concerns.

Enhanced Resilience

One notable advantage of fanless-designed computers is their ability to be made water-resistant and dustproof. Unlike devices with fans that require vents for air circulation, fanless designs can be fully sealed. This enhances their resilience and makes them suitable for use in multiple environments.

Quieter Operation

Fanless designs excel when you require a computer to operate quietly or silently. While the noise from fans may not be significant at lower speeds, it can become disruptive when fans are running at full speed.

Passive cooling systems in fanless computers offer a silent alternative, making them ideal for situations where fan noise would be a disturbance.

Common Applications and Uses of Fanless Cooling

You will often find computers using passive cooling systems in the medical and industrial sectors.

Medical Usage

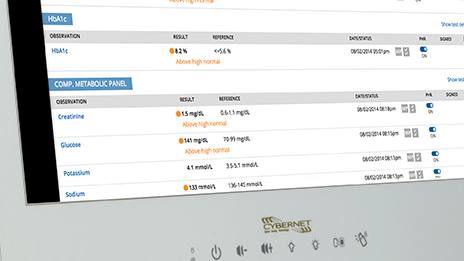

In medical settings, computers must run continuously, demanding frequent cleaning for disinfection while avoiding the circulation of dust particles. Passive or fanless cooling solutions fulfill these essential requirements.

These systems allow medical computers to operate without fans, reducing the risk of fan malfunction during extended operation. Moreover, the fanless design enables complete sealing of the unit, eliminating the need for vents to prevent overheating.

This feature is critical, ensuring that medical devices can be easily maintained without compromising their functionality.

Industrial Usage

Similarly, the industrial sector benefits from passive cooling systems, particularly in factory environments with by dust and grime. Computers play a pivotal role in these facilities, and the need for consistent, reliable operation is paramount. Passive cooling designs alleviate concerns related to fan malfunctions caused by dust accumulation.

Furthermore, fanless computers in industrial settings are more robust due to their fewer moving parts. They are less susceptible to damage from drops or impacts, enhancing their durability and longevity.

As with medical environments, the ease of maintenance without damage risk is an advantage, considering the less pristine conditions in which these computers operate.

Choose Cybernet for Passive Cooling Expertise

For nearly 30 years, Cybernet has been at the forefront of manufacturing innovative computing solutions where passive cooling plays a pivotal role. These cutting-edge technologies provide specialized solutions for various industries, ensuring reliability, efficiency, and ease of maintenance.

Contact a Cybernet expert today to discover how passive cooling can elevate your business operations. Explore the future of computing with Cybernet’s fanless computers and experience the advantages of passive cooling in action.

Advantages of Fanless All-in-One Computers

May 19, 2017

Technology evolves at an increasing speed. Every day brings a new change. Old concepts are redefined. Capabilities never seen before emerge. The fanless PC design and technology under its hood has changed so much since…

0 Comments8 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox