It is unsurprising that the aerospace industry is high-tech. There were nearly 39 million flights worldwide back in 2019. While this dipped in 2020 due to the pandemic, those numbers are expected to increase as restrictions continue to ease steadily.

It’s also expected for each one of those flights to reach its destination safely and deliver its passengers in comfort. A bevy of hi-tech devices like on-board industrial mini PCs helps accomplish this amazing feat. Imagine how surprising it is to learn that planes are are still assembled by hand.

Why is that? Today, we cover how automation is making inroads into the industry and its benefit in constructing commercial airplanes.

Slow Ramp up to Automation in Aerospace

Article Guide

Two significant reasons are usually cited as to why the aerospace industry has been conservative in its approach to automation.

First, aircraft are not only technologically complex but are also enormous in comparison to other manufactured products (e.g., cars.) Components like doors or wheels of even “small” commercial aircraft are too bulky and unyielding to be built in assembly-line fashion like electric car manufacturing, for example.

So, when automation is used in airplane construction, human workers and robots can be found scrambling over a given part. Or they may find themselves needing to travel to another part of the massive warehouse to reach the part that needs to be worked on. This is all in sharp contrast to most automated systems, where a piece is delivered to the robot via the assembly line.

The second and, arguably, the main reason is that production volume numbers in aerospace are significantly lower than in other industries.

For example, the most produced plane in the world is the Cessna 172 Skyhawk. At least 44k have been made since it was first introduced back in 1955.

Or look at the Boeing 737, which took its first flight in 1967. Nearly 11k were built and flown since then.

Impressive numbers, right? Actually, they’re dwarfed by the auto industry. Back in 2020, it’s estimated over 150,000 cars alone are built per day somewhere around the world. Automaker Toyota occupies a big chunk of this figure as it made over 23k cars each day that year.

Again, commercial airplanes are complex to build. They’re also sold at low volumes. This makes aircraft builders reluctant to invest in the high costs of most automated machinery. At the time of this writing, factory automation is primarily being used to support worker productivity. However, recent technological advancements in automation and their accompanying benefits are catching the eye of many industrial heads as backlogs for aircraft continue to grow.

Drilling and Fastening

Drilling holes into components is the task robots are most often used for. Thousands of holes need to be drilled into a fuselage with precision.

Advocates of automation in aerospace point out that robots can do tasks with consistent and speedy results. Even better, they can drill a hole in a single step. On the other hand, a human worker might have to take four steps to drill the same hole with the same precision. Skipping such extra steps helps further reduce costs.

Application of the numerous fasteners along the fuselage receives similar benefits from automation in aerospace.

Moving Massive Parts Safely

Automation also minimizes risk to human workers. As previously mentioned, many airplane parts are enormous. Now imagine moving just a section of the fuselage or wing of the massive Boeing 777X, scheduled to take flight in 2025. At 251 feet, the body of this passenger plane alone is longer than the wingspan of its famous predecessor, the 747.

Robotic arms, under the expert control of a human supervisor and their industrial tablet, can move the parts of this or any other plane to their proper places during assembly. They can do so 24/7 if necessary without risk of injury, like if done manually by workers.

Keeping Workers Safe While Painting and Sealing

Painting, like drilling, is another common task robots are used for in aerospace. They can apply and spray the often toxic coatings and paints evenly and to exact specifications—a vital qualification. Robotic systems applying sealant have been clocked to be 20 percent faster than manual methods, an essential stat in an industry when delays can be costly.

There are other benefits. Robotic painters don’t require scaffolds to get to the aircraft’s top and other hard-to-reach places. Robots with the right flexibility and reach can be brought in and programmed to do so virtually unsupervised. Their use also protects workers from this hazardous task. This also saves on costs (i.e., injuries, sick time, medical leave, etc.)

Closing Thoughts

Bringing automation to aerospace takes a lot of work. The massive proportions of the crafts and the sales of so few of them make aircraft manufacturers reluctant to invest in the sometimes high price of automated machinery. The advantages of automating many tasks (e.g., drilling, movement of parts) common to the industry are increasingly outweighing those costs as well as risks like worker safety.

Contact an expert at Cybernet if your aerospace firm is interested in learning more about automation in aircraft manufacturing and how our computers work well with such systems.

Join the conversation and connect with us on this and other relevant topics – Follow us Facebook, Twitter, and Linkedin.

Types of Industrial PCs Used in Industrial Automation

February 10, 2017

The industrial sector is increasingly experiencing the impact of the Industry 4.0 concept. Whether you are looking to optimize the workflow, increase production or savings in maintenance, or explore new automation…

0 Comments8 Minutes

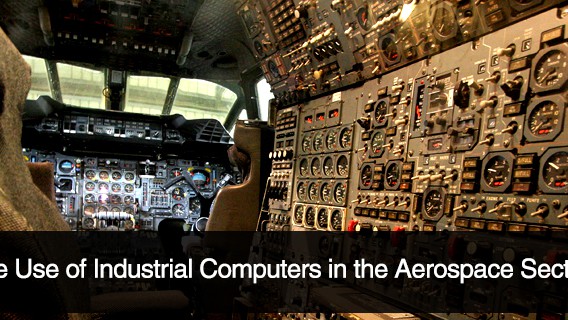

The Use of Industrial Computers in the Aerospace Sector

September 17, 2015

Over recent years, industrial computers have come to take on a critical role in a number of professions. The aerospace industry is one sector that has come to rely on the use of these devices to address a number of…

0 Comments4 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox