The industrial sector is increasingly experiencing the impact of the Industry 4.0 concept. Whether you are looking to optimize the workflow, increase production or savings in maintenance, or explore new automation opportunities, there are many ways industrial automation and the underlying technology can boost your operations.

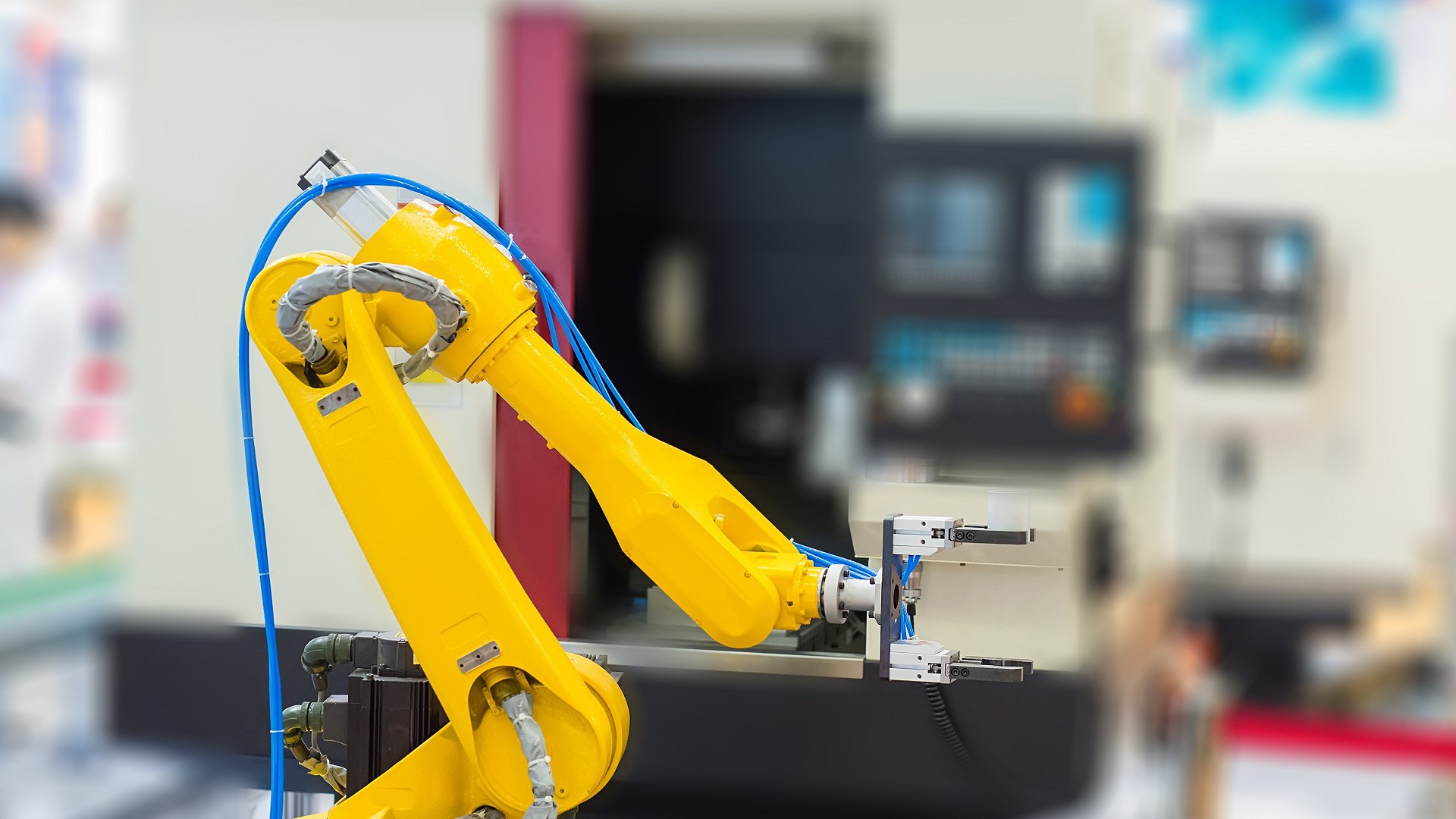

Industrial automation is the automation of technical processes using computer and information technologies. It gains importance as the underlying technologies evolve rapidly, infiltrating more spheres of our working lives. The term industrial automation is used when devices, machines or technical plants work automatically with the help of electrical, pneumatic, hydraulic or mechanical equipment. The machine equipment replaces the human actions. The system, in this case, consists of three constituents [source]:

- A technical plant or machines that perform a technical process, such as transformation, manufacturing, conversion or transport of material or energy.

- A computer or a communication system that processes information from the machines. It acquires, calculates and presents data about the technical events. It also provides the necessary interface for the personnel to control the technical processes.

- The control personnel that observes, controls and influences the technical processes through the corresponding interfaces and adjusts the process in case any disturbances arise.

The aim is to replace as much as possible human labor intervention and hazardous assembly processes with automated machine labor.

In an industrial environment, a wide number of factors influence the choice of the computer for the industrial automation, such as ruggedness, shock, vibration, temperature, pressure, distance, humidity, exposure to liquid, dust, and many other ambient variables.

Mini Rugged PCs

Article Guide

These are versatile, customizable industrial computers that allow adding almost unlimited functionality via full-size and mini PCI Express slots, USB ports, mSATA, RS232 ports. Ruggedness ensures shock and vibration protection, durability, while IP65 sealed waterproof and dustproof build ensures ingress protection from liquids and hard particles, as well as temperature fluctuations. Mini rugged PCs come with military-class high-performance processors that minimize power consumption and maintenance costs. They are compatible with virtually any existing peripherals, and any device in an industrial setting. The multiple PCI Express slots enable it to be configured for nearly any industrial automation functionality. Since many builds are fanless, their cooling system is passive, and thus the PC consumes less power and produces significantly less heat than traditional computers.

Of special benefit is the terminal block feature, which allows the PC to be turned off remotely, so locating it in an enclosure and being able to power on and off the computer makes it more flexible as to where you can mount it.

Mini rugged PCs have many applications in industrial automation:

- Data collection.

- Control card for equipment.

- Industrial imaging and other applications requiring high-speed data.

- Controller in machine vision applications to automate quality control systems.

- Automatic inspection, measurement, verification, flaw detection.

- Direct equipment, for example, robots.

- Video surveillance and analytics requiring HD image capturing, facial recognition, real-time detection, and post analytics.

- Any application that requires removable drive bays for swappable hard drives for easy data backup.

- As embedded computers.

Industrial Open Frame Panel PCs

Industrial panel PCs support industrial communication protocols and accommodate the needs of many industrial applications that allow operators to monitor, control and adjust industrial automation processes. Serial ports and dual NICs allow its use with legacy devices and peripherals, so integrating new equipment and still use the older devices creates saving opportunities.

Open frame panel PCs are designed for seamless installation in industrial environments and integration into an existing architecture of a production chain – in control cabinets, machines, kiosks, etc. They are widely used for Human Machine Interface, as its resistive touch screen and ruggedness ensure easy data access and durability under harsh environments. Open frame panel PCs are widely used for:

- Original equipment manufacturer machinery, OEM.

- Human-Machine Interface, HMI.

- Machine-Machine Interface, MMI.

- Internet-of-Things control and data aggregation.

- Vision systems.

- Factory automation systems.

- Material handling.

Industrial Tablets, Forklift Tablets

Companies see the wisdom in deploying industrial tablets on the manufacturing floor for a variety of applications:

- Human-Machine Interface – instant access to critical data with notifications from industrial automation systems, status information, machine vision system notifications.

- Instant remote control of industrial processes.

- Any application that relies on the cloud-based platforms and machine-learning monitoring systems that detect anomalies in automation systems and enable predictive maintenance of industrial equipment.

- HMI-hosting web servers host large volumes of data about production statistics, maintenance and diagnostics. Since industrial tablets pull the data from the cloud, employees do not need to plug in (as with laptops) and can change parameters remotely.

- Numerous warehouse and inventory tasks automation with embedded barcode reader or RFID reader for quality control, items tracking and security, for example for scanning barcodes on raw materials and finished goods.

- Forklift tablets are popular due to their ruggedness, easy yet reliable mounting, hot-swap batteries and versatility. Forklift tablets are used in HMI, MMI, barcode scanning and inventory management, processes control and monitoring. They ensure 24/7 uptime and withstand shock, vibration and other harsh conditions.

- Industrial tablets are widely used for assembly line balancing.

- Linux and Windows-powered rugged tablets are used for embedded systems, factory automation, tracking and tracing, eliminating paperwork, capturing signatures.

Benefits of Industrial Automation

- Increase labor productivity – get greater output without losing accuracy.

- Improve product quality, reduce defect rate, increase conformity and uniformity of the quality.

- Reduce production cost, labor cost, increase ROI.

- Reduce routine manual tasks such as variables monitoring.

- Improve safety by locating the human worker outside the hazard zone, thus preventing accidents and injuries.

- Advance remote performance monitoring, diagnostics, set point computations, startup and shutdown operations, critical notifications, reporting and remote control of automated processes.

Benefits of Industrial Computers and Rugged Tablets

- Rugged builds, water- and dustproof, IP65 sealed, shock, vibration and temperature fluctuations resistant.

- Military-class computation power.

- Power-efficient.

- Fanless, passive cooling.

- Hot-swap drives in panel PCs – perfect for data backups.

- Hot-swap batteries in tablets for 24/7 uptime.

- MIL-STD components, 5+ years lifespan, low fail rates, extended warranties, customized builds.

- Integrated peripherals – barcode, RFID, CAC, Smart Card, biometric.

- Ease of mounting with VESA.

- Ease of integration with legacy ports, support for industrial protocols and Windows or Linux OS.

Industrial Panel PCs and the Internet of Things

September 7, 2018

The “Internet of Things” has become the hottest buzzword in tech circles. It refers to the practice of physical items outfitted with electronics that allow them to connect to the internet and exchange data with other…

0 Comments7 Minutes

Automating Production with Industrial PCs

March 1, 2018

The idea of "build the machine, build the empire" has been a concept since the dawn of the industrial revolution in the 18th century. Machines are largely the force behind manufacturing today for mass produced goods.…

0 Comments6 Minutes

The Role of Industrial Computers in Industrial Automation

July 2, 2020

Industrial automation, as the name suggests, refers to using industrial computers in order to automate industrial processes. It may be understood as an umbrella term for computer automation of design, manufacturing and…

0 Comments9 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox