Industries from retail to manufacturing to healthcare manage many moving parts on a daily basis. A barcode reader for an inventory management system makes this necessary task much easier. Workers know where an item is at all times, whether groceries are to be shipped or a patient is waiting for a bed in the ICU. The result is increased productivity, accuracy, and customer satisfaction for everyone involved.

- What are Barcodes, Barcode Scanning, and Inventory Management Systems?

- Barcode Scanning Options

- Types of Inventory Management Systems

- Uses of Barcode Readers in Inventory Management Systems

- Special: Barcode Use in the Healthcare Industry

- Benefits of Barcode Readers for Inventory Management Systems

- Buying Barcode Readers for the Inventory Management Systems

What are Barcodes, Barcode Scanning, and Inventory Management Systems?

A barcode is a graphical representation of data. The most familiar versions are those black-and-white parallel bar labels on most grocery and retail items. Another type, the QR code, looks like a square or rectangle grid filled with black-and-white squares.

Regardless of their appearance, barcodes represent data about that particular item. For grocery items, this could be their SKU number and price. Others, like manufacturing, provide the date of manufacture and expiration, if applicable.

Barcodes are also used to keep tabs on people in certain industries. In healthcare, barcodes on patients' wristbands provide personal information (name, DOB, etc.) as well as their primary physician and prescription information. This reduces possible mix-ups and their consequences.

Barcode readers, also called barcode scanners, are devices that scan and decode the data to send to inventory management systems.

Inventory management systems (IMS) manage that barcode data. Housed in industrial computers (or medical-grade PCs for hospitals and similar facilities), these systems store, identify, and track all relevant information. Users thus can always have a real-time picture of what is happening with the inventory and plan accordingly.

Barcode Scanning Options

Most barcode scanning setups consist of readers and scanners, linked computers, and printers to create the barcode labels. Popular or well-known ones include:

- Laser scanners - As their name implies, these devices scan barcodes using laser beams.

- CCD readers - These readers have sensors to measure the light coming from the barcode instead of self-reflected light hitting it from a laser.

- Camera-based barcode scanners - Unsurprisingly, this scanner takes a picture of the barcode, which is then examined by IMS. Camera-based scanners are primarily used to read QR codes.

- Handheld barcode readers – Portable gun-like devices held in the user's hand. Users simply point it at the label to scan the barcode.

- Fixed-position barcode readers - These readers are unmoving or stationary. An example would be a handheld barcode reader locked into place by a stand. Items are passed underneath them to be scanned.

- Presentation scanners – These are flat surfaces that read barcodes swiped across them. They are frequently found at grocery stores and outlets.

Types of Inventory Management Systems

Today's inventory management systems are software that store, manage, track, and optimize a company's inventory in an organized fashion. They generally break down into four types:

- Days Sales of Inventory - DSI processes inventory based on how long it takes to be sold.

- Economic Order Quantity - EOQ restocks inventory based on how much each order is sold. The aim is to reduce overall costs.

- Just-in-Time Management - JIT keeps just enough inventory on site to be sold within a certain amount of time.

- Materials Requirement Planning - MRP orders the supplies to manufacture products based on sales forecasts.

Most companies use more than one IMS.

Uses of Barcode Readers in Inventory Management Systems

As previously mentioned, barcode readers have found many uses in numerous industries. Four notable ones include:

Product tracking

Unsurprisingly, product tracking is among the most popular uses of barcode readers for IMS. With it, businesses can monitor the status and location of products supporting their daily operations, whether the raw material used or the final item itself.

Asset tracking

Assets are those items that companies own that aid in their productivity. The machinery to manufacture the company's products, industrial tablets used by field workers, and company cars and airplanes are examples of assets. They can be affixed with barcodes, which IMS then tracks.

Invoicing

With this application, companies place barcodes on invoices. This makes it easier for their IMS to scan, track, and process for accounts payable and accounts receivable. Both are updated, for example, when the customer pays the invoice and a worker scans its barcode.

Special: Barcode Use in the Healthcare Industry

A special mention needs to be made about using barcodes in the healthcare industry. While inventory, like medical devices, equipment, and supplies, is tracked by IMS, there is no direct system for patients. Electronic medical records (EMR) are the closest system, and are used to follow:

Medication administration

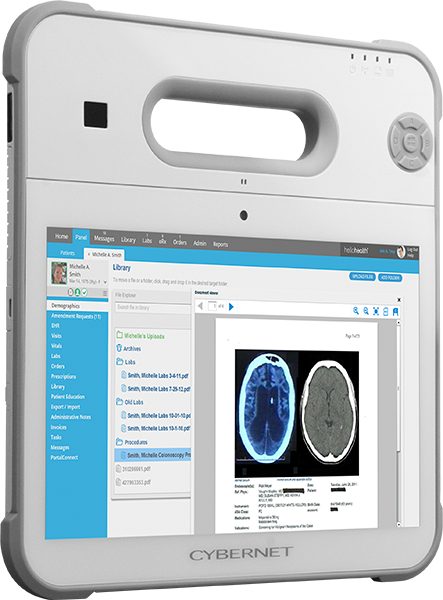

As mentioned earlier, the barcodes on a patient's wristbands contain their name, primary provider, and medication information. Staff can quickly bring up this information and their EMR with a built-in barcode reader on a medical-grade tablet. The setup ensures that the right patient gets the correct meds and at the proper doses.

Specimen collection

In this use of barcodes, specimens collected by patients (blood, urine, etc.) are tracked as they're sent to labs for processing. The results are then uploaded to the proper EMR for review.

Benefits of Barcode Readers for Inventory Management Systems

The familiar black-and-white barcode has been around since 1991, though the technology can be traced back to the Seventies. Regardless, modern industries have benefited from barcodes, their readers, and IMS providing:

Greater accuracy with fewer errors

Workers make mistakes, from jotting down the wrong price to reversing dosage figures of medications (96 ml versus 69 ml). There are far fewer chances of errors with barcodes as they don't suffer fatigue, distractions, and boredom. (It should be noted that errors in the barcodes themselves are extremely rare.)

Real-time data

Inventory management systems are updated each time a barcode is scanned. Companies now have constant, real-time information on their inventory and sales. This makes it easy to calculate vital metrics from the IMS, like the value of inventory on hand or the week's point-of-sales (POS) per item.

Low cost of entry

Barcode readers are inexpensive and straightforward to set up. Companies need a computer to store data, the readers, and a label printer. They can start by printing a limited number of barcodes for internal use and expand as needed. Costs remain low, especially compared to more advanced solutions like RFID systems. IMS can be scaled to match the company's growth, providing whatever level of detail is available through the software.

Minimal training

Training new employees to track inventory manually could be a daunting process. This is especially true for medium-to-large companies or those with numerous products, like a typical department store. Thanks to their ease of use, barcode scanners practically eliminate such training. Even a new hire can be up and working productively within minutes.

Buying Barcode Readers for the Inventory Management Systems

So you've decided an IMS with a barcode reader is the right setup for your business. Here are some tips on selecting the right one.

What are your goals?

Understanding your specific needs will narrow your choices to the right barcode readers and IMS. Are you looking for greater accuracy? The ability to forecast with greater predictability? Or a simple system to get your company to meet its quarterly profits?

Which scanning technology?

Barcode readers use lasers, light, or cameras. Each one has advantages and disadvantages. The distance from the scanner to the barcode can affect performance. You'll also want to check the durability of the scanning equipment. For example, handheld scanners for warehouse use must be durable enough to withstand being dropped and banged against objects. On the other hand, presentation scanners like those used at grocery stores will not need to be so ruggedly built.

How do the barcode reader and inventory management systems connect?

How will data be transferred between the barcode reader and IMS? While many use Wi-Fi, readers can be plugged into rugged mini PCs via USB-C cables. Both have advantages and disadvantages.

What's the price tag?

Finally, consider your budget. Simple, handheld barcode readers cost between $50 to $500 per unit. Larger or more complex ones, like grocery store presentation scanners, unsurprisingly cost thousands. Inventory management systems have a similar price spread, from the hundreds for monthly subscriptions to tens of thousands for large and complex networks.

Selecting the Right Barcode Reader for IMS with Cybernet

Businesses today have to deal with many moving parts, and tracking them all can be challenging. Pen-and-paper, file cabinets, and similar manual methods just can't cut it. Technology like using barcode readers for inventory management systems has emerged to meet the challenge.

Contact an expert at Cybernet if your business is looking to use barcodes to track inventory. Our industrial and medical computers are built to connect right away with most scanners and readers on the market today. We even have models with them already built. Just turn them on and start scanning!

And if our pre-built PCs are not to your liking, don't worry. We're an original equipment manufacturer, which gives us total control over our devices. We're confident we can custom-build the computer(s) to your exact specifications.