Few industries are more exciting or hold more potential for the future than aerospace: a merging of science, business and engineering to literally reach the skies. When most people think of the term, they think of planes, satellites and space shuttles, but the aerospace industry is actually quite diverse, with applications in the military, heavy industry and commercial endeavors.

Computers play a vital role in the field of course, and considering both the complexity of aerospace endeavors and the need for powerful systems that can withstand all manner of punishment, a standard out-of-the-box commercial system is simply not going to do the job. Industrial PCs, with the right features to handle both the computing necessities of the job and the physical demands that the aerospace field often places on it, makes a far better solution. How, exactly? Here are a few examples of the ways aerospace companies make use of the unique features of rugged computers.

Industrial Tablets Make Aircraft Maintenance a Snap

Article Guide

Maintenance is an ongoing process when it comes to aircraft: constant, ever-present and exceedingly important for obvious reasons. Maintenance personnel must often rely on mobile computers to do their work, since aircraft can’t exactly be parked at an office workstation. Furthermore, rugged PCs are an absolute necessity owing to the bumps, shocks and vibrations that can often occur around airports and aircraft.

For example, a crew may need to call up a 3D image to assess any potential issues, as well as schematics and technical documents, which the tablet needs to provide swiftly and without error. They may also require flight-related data to determine when and where a given piece of damage took place. In some cases, they may even need the tablet to help search for signs of damage with the aid of an ultrasonic detector. All of that requires a lot of processing power, and the tablet used needs to be up for the job.

An industrial tablet is usually lightweight and has an ergonomic grip, allowing maintenance teams to carry them around easily and use in one hand. Furthermore, a rugged chassis that meets MIL-STD-810G standards will keep it running even if it takes a tumble, and that you don’t need to worry about unexpected jolts while performing your work.

Jettisoning Paper Manuals Saves More than Just Trees

Tablets in the cockpit can be applied to simpler problems as well. Consider, for example, the case of technical manuals required to be carried on all flights. That includes pre-flight checklists, the aircraft’s operating manual, logbooks, navigation charts, and even maps of airports. (Pilots used duffel bags to carry them all.) Paper flight manuals can add up to 40 pounds of weight. It may seem like a trivial amount of weight (about the equivalent of a single carry-on item), but every pound uses more fuel. When you multiply that by hundreds of aircraft making several thousand flights per day, that fuel cost adds up.

Industrial grade tablets within the cockpit are being used to replace those manuals instantly while ensuring that the information is always present and accessible. Tablet PCs and rugged PCs weigh considerably less than all those manuals. These are known as electronic flight bags, or EFBs. For example, American Airlines estimated that their electronic flight bags conserves over 400,000 gallons of fuel per year, which translates to over one million dollars in saved revenue per year (depending on the price of fuel). Now imagine all of the other areas of the plane where a mini rugged computer or industrial tablet can replace older, heavier equipment. The savings doesn’t just have to be enjoyed by large commercial airliners either. Any size aircraft can gain efficiencies by making the switch.

Rugged PCs for Aeronautic Vehicles

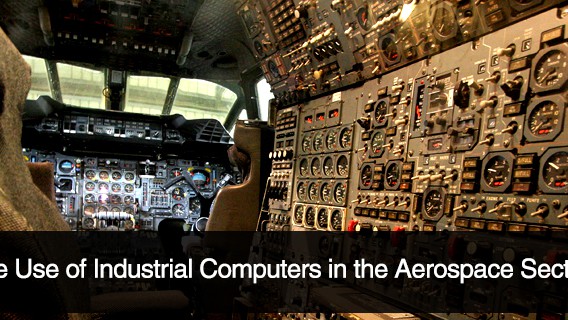

When it comes to planes, helicopters and other aerospace vehicles, the information at the pilot’s fingertips is vital. Space is at a premium in any cockpit, and yet pilots depend on a staggering array of instruments and gauges to give them the data they need. Ideally, that data should be updated with real-time information on issues such as incoming turbulence, news of airport closures and similar concerns that can drastically affect flight operations.

A rugged industrial PC provides some streamlined answers to cockpit issues. Rugged PCs are usually very small, requiring minimal space to function. Yet they can provide significant processing power, and can stand up to the bumps of take-off, landing, and turbulence as well as the temperature extremes that come with most types of flight. Industrial computers can also be customized to include legacy ports like an RS-484 port allowing multiple devices to be hooked up to and controlled by a single computer. This means reduced weight, less maintenance, and fewer computers that need to be connected and synced, all in a rugged design that is built to survive when the friendly skies aren’t so friendly.

The Future and “The Airborne Internet”

The concept of the Airborne Internet first arose in 1999, as part of a NASA planning conference. It envisions aircraft in flight creating a digital data network that allows them to exchange information not only with other aircraft, but with flight control on the ground. As of this writing, several companies have completed proof-of-concept tests and are engaged in further trial runs.

The interconnected planes form a “mesh” network, which means there is no single point of failure the way there is with towers or satellite systems. If the computer in one plane suffers a disruption, the signal simply shifts to the next plane in the link. With redundant data paths, the network becomes more reliable and provides real-time performance for aircraft making use of the system: eliminating the time delay present in satellite-based Internet access. Such a system would cost less than launching satellites into orbit as well.

The Airborne Internet is still more concept than reality at this point, but as the aerospace industry moves forward, it could become the norm in just a few years. Industrial tablets and rugged computers will play a key role in this process. Powerful processing capacity and the ability to handle airborne conditions such as low temperatures and unexpected turbulence makes them ideal for providing in-flight broadband services. Through such PCs, onboard passengers can be given Internet access via tablets in their seats, while pilots can receive vital data concerning weather and ground-to-air communication without suffering any time delay.

Cybernet Manufacturing offers rugged computer systems that can stand up to the tough conditions demanded by the aerospace industry. If you work in the field – or even if you just require a system that can handle similar rigors – contact us today.

The Use of Industrial Computers in the Aerospace Sector

September 17, 2015

Over recent years, industrial computers have come to take on a critical role in a number of professions. The aerospace industry is one sector that has come to rely on the use of these devices to address a number of…

0 Comments4 Minutes

Why Choose Rugged Tablets over Consumer Tablets

January 12, 2016

As technology continues to play a more integral in the way companies operate, many are now opting to use mobile tablet computers for their business purposes. In fact, According to Quarterly Mobile PC Shipment and…

0 Comments4 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox