Regardless of whether we’re discussing a B2B-based manufacturer or one that sells directly to consumers, the order to cash process is an essential one and one whose optimization should be prioritized. Thankfully, as complicated as the process is, because it’s so complicated and involves so many steps across key stages in the manufacturing process, it’s very likely much of the smart manufacturing initiatives that have already been implemented within your facility can be leveraged towards enhancing the order to cash process.

More specifically, the foundation of most smart manufacturing initiatives, the industrial computer, can be used in several creative ways in order to help enhance the order to cash process.

What is Order to Cash Process?

Article Guide

The aptly named order to cash process, is a collection of processes that take place from the time an order is placed by a customer to the moment the manufacturer receives payment for their service or product. Of course, supply chains can vary from business to business, but this process usually follows these general steps:

- The customer places an order

- The manufacturer verifies that the ordered product is available

- The order is prepared and prepared for shipping

- Inventory numbers are updated to reflect the order

- An invoice is sent to the customer

- The manufacturer receives payment

- Customer service is provided in case any issues such as refunds arise

The process can sound pretty all-encompassing because it is. The order to cash process is one that holds weight in practically every stage in the supply chain, meaning inefficiencies in the process may as well be glaring holes in your factory’s optimization efforts. A poorly laid out order to cash process can result in a number of disruptions. Poorly planned inventory, for example, can mean wasted money on excessive stock or not having the stock needed to fulfill customer orders. Something like improper billing at the end of the cash to order process can delay or even eliminate payment for costly services delivered by your facility.

How can Order to Cash Process be Improved?

There is an immeasurable amount of ways that the order to cash process can be improved. Many of these means involve, like several other manufacturing initiatives, enhanced supply chain visibility, a topic we’ve covered ad nauseam on this blog. Below, however, are a few order to cash best practices specifically centered around your facility’s computer workstations and software.

1.) Automated Order Processing

As baffling as this may seem considering manufacturing’s love affair with all things automated, according to Manufacturing.Net, more than 80% of manufacturers and distributors still process customer orders manually by hand. And it doesn’t take a genius to realize that the potential for human error when manually recording orders is immense.

What’s worse, manual order processing has the potential to impact multiple stages of the order to cash process, not just fulfillment. If a facility is tasking their customer service teams with manually punching in data from sales orders, that team is spending time and bandwidth that can’t be spent actually speaking to customers, meaning both refunds and customer service are now being impacted IN ADDITION to order processing.

Thankfully, automated solutions do exist for the order processing stage. Tools like Conexiom’s allow for sales reps and customer service team members to receive order documents and then quickly scan and convert the data found into a format that can be thrown onto whatever order management system your team uses to process orders. This ensures accuracy, speeds up how long it takes to process an order, and opens up more manpower for customer service, what the team was hired to actually do.

2.) RFID Inventory Management

After order processing comes inventory management. Manufacturers need to constantly be aware of just how much inventory of a certain product is available to ensure orders that are processed can actually be fulfilled. Not only that, inventory needs to be quickly updated after an order is placed as well to ensure stock is accurately measured for the next order that comes through.

Arming floor level employees with a rugged windows tablet with RFID scanning capabilities can give them the ability to quickly scan products in as they’re delivered and returned and out as they’re ordered and sent. Again, this eliminates manual error, speeds up the process since scanning a product takes seconds, and improves efficiency.

3.) Robotic Process Automation

Robotic process automation software, in addition to the industrial computers that can scan in inventory, can be used to further optimize the order to cash process. We’ve discussed before how many have begun using the enterprise-based software to streamline the creation of Bills of Materials, lists of raw materials and parts used to create a product.

Using this software in conjunction with RFID capabilities that can scan in the amount of raw materials available can ensure your team is constantly in the know as to whether or not they have the materials necessary to fulfill orders as they come in.

4.) Optimize Order Picking

Order picking, the practice of picking products from a warehouse in order to organize and fulfill customer orders, is an essential procedure for any manufacturer and one that requires proper optimization, especially if we’re looking to enhance the order to cash process. After all, the procedure eats up as much as 55% of some warehouse’s operation costs and even as much as 70% of the time spent within a distribution center. Optimizing these order picking processes with the right industrial hardware, naturally, can’t be overstated.

Thankfully, there are several methods of order picking and order packaging, each with their own benefits. Once you’ve picked a picking process that works best with your particular factory or plant, you can start to see increases in order accuracy as well as efficiency in how quickly those orders are packaged and sent out to customers. Even more thankfully, these order picking processes become a lot easier to ideate and implement once you’re gathering real-time inventory updates from your RFID-equipped tablets and rugged PCs.

Find the Flaws in Your Order to Cash Process, Then Form a Plan

Making a case for optimizing the order to cash process isn’t really necessary. It’s common sense that you’d want to make such a core process of your supply chain more efficient. What we’re making a case for, instead, is taking a more personalized approach to that optimization. Take a moment to learn how and where your particular order to cash process is failing or isn’t moving as fluidly as it could be. Only then can truly effective means of optimization take place. For more information on how you can find these holes in your order to cash process and the hardware needed to improve it, contact an expert from Cybernet today.

The Role of Industrial Computers in Industrial Automation

July 2, 2020

Industrial automation, as the name suggests, refers to using industrial computers in order to automate industrial processes. It may be understood as an umbrella term for computer automation of design, manufacturing and…

0 Comments9 Minutes

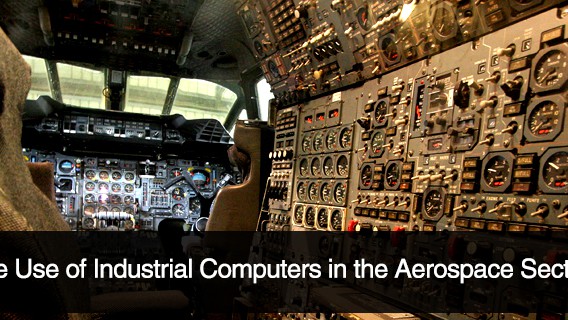

The Use of Industrial Computers in the Aerospace Sector

September 17, 2015

Over recent years, industrial computers have come to take on a critical role in a number of professions. The aerospace industry is one sector that has come to rely on the use of these devices to address a number of…

0 Comments4 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox