How HIT is Simplifying Preventive Care

Disease and disability can be brought on by a number of factors, namely,…

How Rugged Industrial Tablets Streamline Logistics

Though it often gets overlooked in our day-to-day lives, logistics – or…

Examining Solutions for Patient Safety in Hospitals

Since the passing of the Affordable Care Act (ACA), hospitals have had to…

How Medical Computers Help Eliminate ER Waste

There’s no denying that waste abounds in the American healthcare system.…

The Women Who Shaped the History of the HMI Interface

International Women in Engineering Day takes place every year on June 23rd. It…

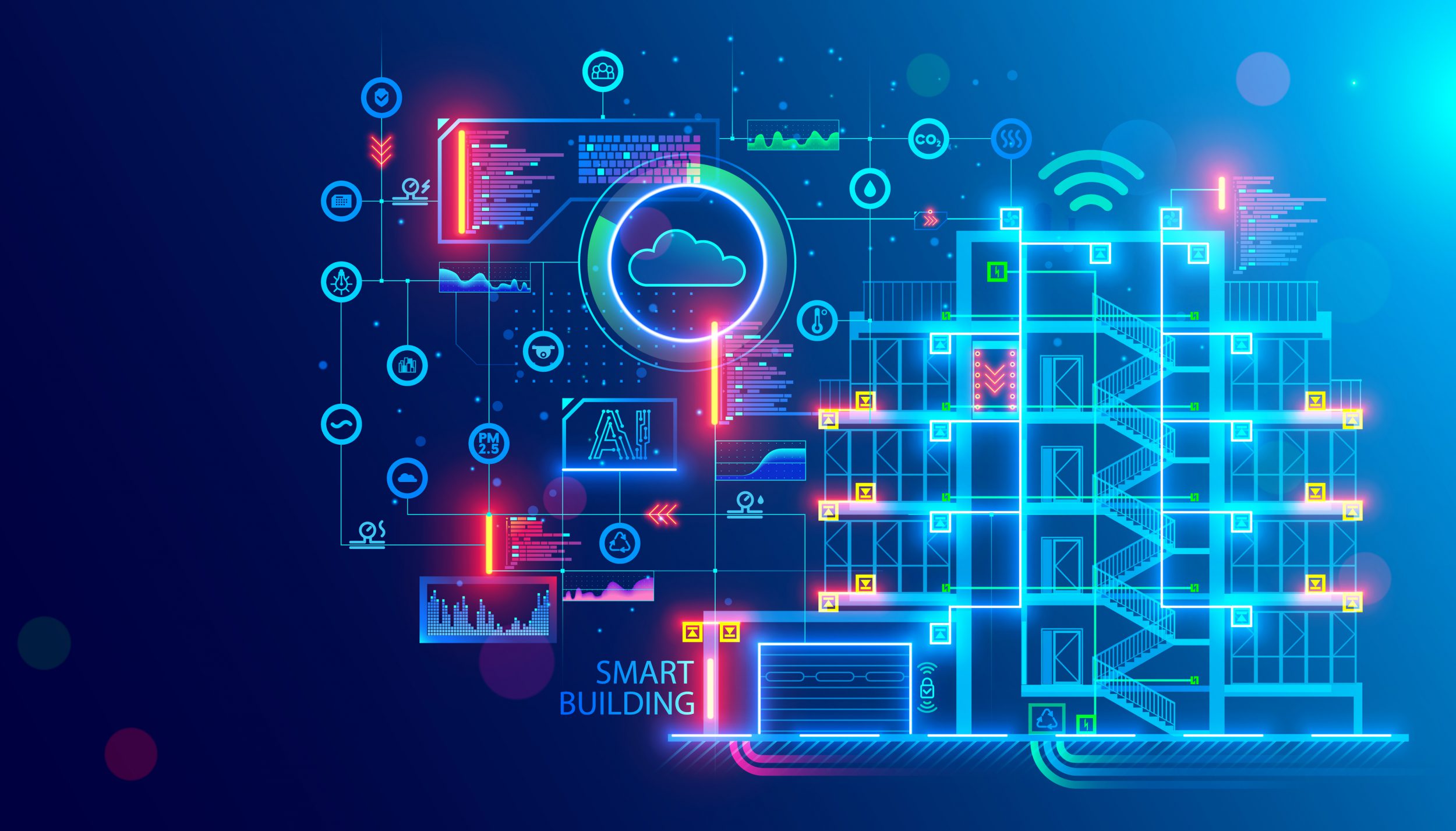

How Industry 4.0 Can Make HVAC Factory Friendly

Many people see being an HVAC (short for Heating, Ventilation, and Air…

How Medical Computers Make Life Easier for CNAs

Every year, we celebrate Career Nursing Assistant Appreciation Day on the very…

Medical Tablets are Bridging the Gap in Behavioral Health Care

Complete health care is premised on the idea that people have a spectrum of…

Industry 4.0 & the Next Generation of Manufacturing Workers

Millennials, am I right? These kids with their safe spaces and avocado toast,…

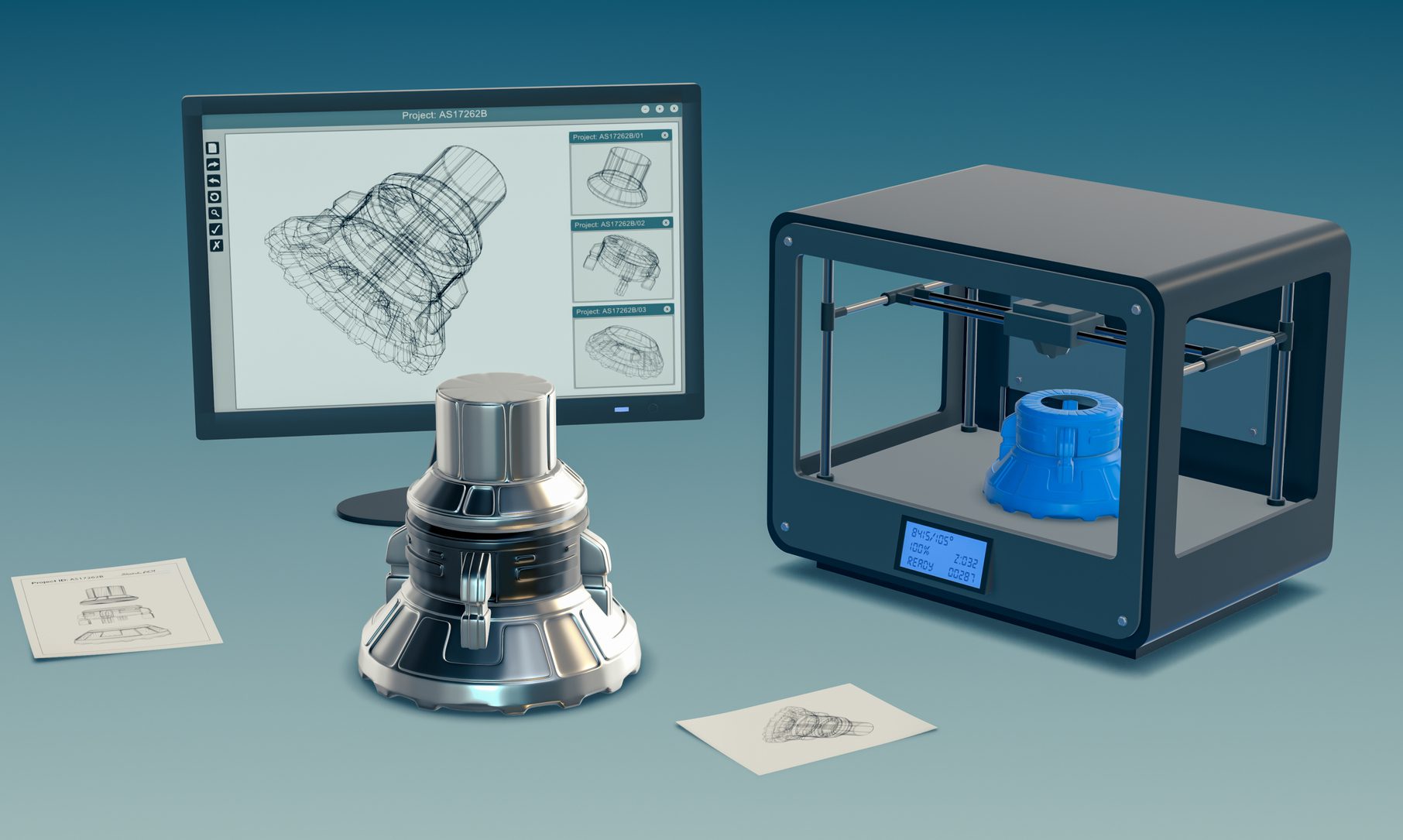

How 3D Printing is Simplifying Repairs in Manufacturing

3D printing, also known as additive manufacturing, is a production process…