Millennials, am I right? These kids with their safe spaces and avocado toast, when will they learn that the world…

Just kidding! Had you going there for a second. In actuality, the oldest millennials are turning 40, and the rest are in their thirties or late 20s by now. Many of the youngest millennials have been in the workforce for a decade, depending on how old they were when they got their first job. They aren’t the next generation of workers; they’re the current generation of workers.

The NEXT generation of workers is Generation Z, or “zoomers,” as the kids say. They’re posed to make up a third of the global workforce by 2025. Like the generations before them, they have their own unique tastes, sensibilities, and expectations informed by the events of their upbringings.

Unfortunately, the reality is that the manufacturing sector has been struggling to attract members of both generations for some time now. And that was before the economy-wide labor shortage set in with the pandemic. So the real question isn’t “how to meet the needs of the next generation of manufacturing workers?” Instead, it’s “how can manufacturing compete in a changing labor market?”

A New Set of Expectations

Article Guide

Millennials and zoomers are different cohorts with different sensibilities. Millennials came of age with the internet; Gen Z was born into it. Millennials are still profoundly affected by 9/11 and the 2008 recession, while zoomers barely remember either event if they were alive for them at all. Millennials are starting to settle down, while Gen Z is just deciding what they want out of this whole “adulthood” thing.

Yet despite these differences, more of their sensibilities overlap than do not. So if you aim to cast as wide a net as possible, it behooves you to appeal to those sensibilities that straddle both generations.

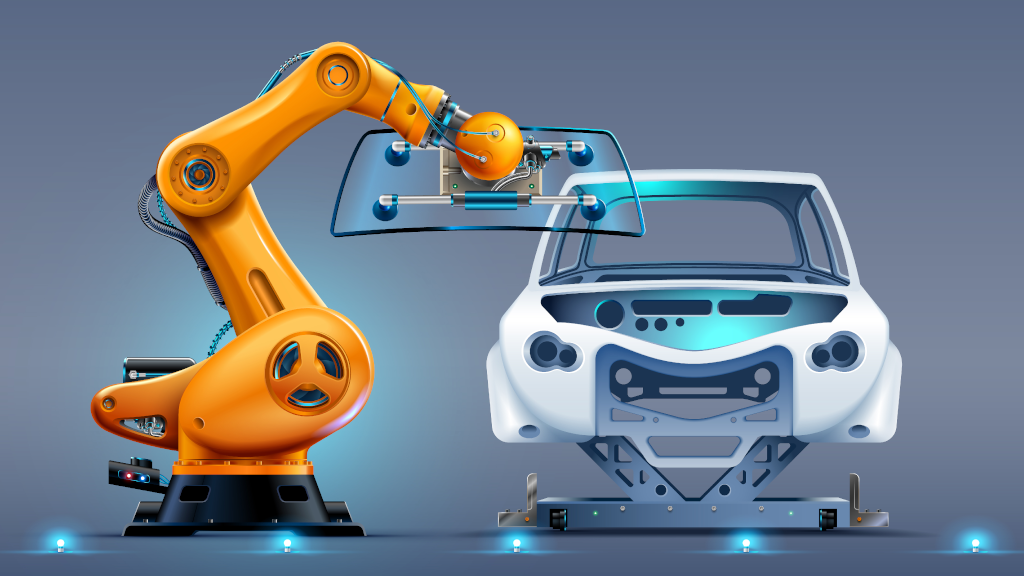

Embrace Technology

If there’s a single trait that unites Millennials and Zoomers, it’s their extreme fluency with digital technology. By and large, members of both generations are deeply embedded in the digital world, and they expect that world to follow them into the workplace. In fact, a recent survey conducted by The Workforce Institute at Kronos found that roughly 40% of both millennials and zoomers believe “outdated processes and technology make their job harder than it should be,” compared with just 20% of boomers and 34% of Gen Xers who feel the same way.

To appeal to this sensibility, manufacturers need to embrace the latest Industry 4.0 technology. No longer is it enough to have a few computerized machines in your facility. You need to highlight how every worker on your factory floor has been issued a Rugged Industrial Tablet that allows them to visualize data from sensors deployed across every part of your operation. Prospective workers need to know that they won’t just be monotonously scanning inventory one by one with a barcode scanner, but rather that they can quickly scan every item on a shelf in one go because their industrial tablet has an RFID scanner built-in. They need to know that they’ll be able to put on Mixed Reality Glasses to see a 4-d digital twin of the factory floor.

In short, millennials and zoomers need to know that the digital fluency they’ve spent their entire lives building will be useful in their professional lives. Moreover, they need to know that they’re not just cogs in an assembly line but rather an integral part of a workflow that brings the digital and real worlds together in fascinating ways.

Industry 4.0 Fosters Greater Work/Life Balance

It may sound like a massive cliche, but young people do not see the size of their paychecks as the only measure of success. While it is undoubtedly true that younger workers still seek out financial comfort and stability, they also don’t want their jobs to overtake their entire lives. Instead, they want to feel that their work adds value to a fulfilling personal life outside of their job. One key element to providing that is fostering a company culture that minimizes workplace stress and burnout.

Obviously, generous benefits packages featuring ample vacation time, child care, mentor-mentee programs, continuing education, and other perks will go a long way to building a more humanistic company culture. However, if the job itself is tedious, repetitive, stressful, physically taxing, etc., young people will still find themselves getting burned out quickly. Fortunately, just as Industry 4.0 technology can increase your operational efficiency, it can make young worker’s jobs more enjoyable and less stressful.

Eliminating Monotony and Relieving Burnout

The first and most apparent way Industry 4.0 technology can alleviate burnout among a younger workforce is by eliminating monotony. One example mentioned above is using RFID readers to scan inventory rather than barcodes. Another is using smart cameras and sensors to assist in quality control.

Rather than having a worker manually check each item off the conveyor belt, a series of smart cameras and weight sensors can check items for physical defects instantaneously. The data is sent to a Mini Rugged PC, which processes it and alerts a worker with an Industrial Tablet when it catches a faulty product. This way, the worker only has to respond when the system detects a defective product, eliminating the monotony of personally inspecting each item.

Though we’ve only mentioned a couple of Industry 4.0 applications here, the potential of the technology is truly limitless. If you want to remain competitive in a more youth-dominated labor market, you need to leverage the power of this new technology to eliminate much of the monotony many people associate with manufacturing jobs.

The Factory Floor is Everywhere

For many millennials and zoomers, work-life balance means not feeling chained to the workplace. Unfortunately for manufacturers, though the pandemic has radically redefined the potential of “remote work,” manufacturing is still not considered an industry where much remote work is possible. With Industry 4.0, that is changing, however.

Now, by strategically employing digital sensors, smart cameras, and smart machinery, at least some of your workers can spend part of their workweek away from the factory itself. Industrial PCs take in all the data and send it to the cloud. If you combine this data with a digital twin or a digital model of your factory floor, you can create what is known as a 4-d model.

Your young, tech-savvy workforce can then access this model anywhere in the world. They can see what’s going on on the factory floor in 3d and in real-time and use the information they receive to remotely control the machines on the floor or contact those workers who are physically in the factory to address issues.

By strategically utilizing the latest technology, you can increase your operation’s efficiency and profitability and free up your workers to do their jobs from anywhere.

Final Thoughts

As enjoyable as it may be to poke fun at the quirks and perceived naivete of younger generations, the truth is that they are the future of every industry. To survive in a 21st-century business environment, you need to recognize and cater to their unique desires and needs. And while we cannot remake your company culture, we can help you bring the digital end of your operation into the modern era. If you’re interested in seeing how digital technology like Industrial Pannel PCs can help your business compete in today’s labor market, contact the experts at Cybernet Manufacturing today!

Policies That Could Change the Manufacturing Industry Overnight

August 8, 2019

There’s no denying that automation is the future of manufacturing: it would be impossible, considering its pretty much the present of manufacturing as well. And while news that “all robots will replace our jobs” in the…

0 Comments7 Minutes

The Use of Industrial Computers in the Automotive Industry

August 20, 2019

The automotive industry invented automation: it’s no surprise that they’ve embraced industrial computers faster than any other field of manufacturing. Because automotive manufacturing requires flexible solutions that…

0 Comments7 Minutes

How Industry 4.0 Will Address the Manufacturing Talent Shortage

October 20, 2020

There’s been a rather peculiar, seemingly contradictory, trend coming out of the manufacturing industry the last few months. According to a report by the Institute for Supply Chain Management, manufacturing activity…

0 Comments10 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox