The average industrial computer faces stresses that consumer-grade PCs never have to consider. Extremes in temperature, shock, vibration, and debris getting inside the computer threaten to damage or even destroy the device.

Fortunately, industrial computers and tablets are designed with these harsh operating environments in mind. By using rugged, military-grade components and integrating the right design features, an industrial computer can be prepared for even the worst its working environment can throw at it.

In today’s article, we’ll break down the most common threats that industrial computers face and how they can be designed to counter them.

A Helpful Definition for “Military-Grade”

Article Guide

The term “military-grade” is thrown around quite a bit when referring to products and equipment. Sadly, some companies use the term irresponsibly, especially when the product in question has no actual military application. When it comes to computers, however, “military-grade” means that the device in question meets Military Standard 810G. MIL-STD-810G lists the requirements and testing methods for physical threats computers can face in military service, such as temperature changes, humidity, bullet impacts, and more.

Obviously, no one expects their industrial mini PC to get shot at, but computer manufacturers still find parts of MIL-STD-810G helpful in developing their own devices. In particular, manufacturers will often test their computers to MIL-STD-810G’s standards for temperature, vibration, and debris protection to demonstrate their qualifications.

Extreme Heat

Even novice computer users understand that high temperatures are bad for a PC. At extreme heat (150 degrees Fahrenheit/70 degrees Celsius), the electrical resistance of computer components begins to drop, which lets more current flow through sensitive parts. Heat can also damage a tablet’s batteries and reduce their effectiveness. At the extreme end of things, the solder used to connect components can melt and cause parts to fall off the motherboard!

The Solution

To counter a high-heat environment, industrial computers rely on fanless cooling and low-power components. Fanless cooling keeps the computer from overheating without relying on fragile fans. At the same time, low-power components generate less heat and are thus less likely to reach dangerously high temperatures to begin with.

Extreme Cold

On the other end of the spectrum, extreme cold is also a problem. When a computer boots up in chill temperatures, its circuits go from cold to hot very quickly, which can cause them to expand and deform. Hard disk drives (HDDs) that rely on fluid dynamic bearings to spin the hard disk’s platter can experience thickening or freezing, which slows the platter’s spinning and makes writing and retrieving data slower. Lastly, condensation can form inside the computer’s case, which leads to corrosion and electrical shorts.

The Solution

In addition to using military-grade parts that are less likely to warp under temperature changes, a sealed case and fanless design help prevent condensation from forming inside the computer. Lastly, industrial computers will typically use solid-state drives (SSDs) instead of HDDs, which do not rely on fluid dynamic bearings and are therefore immune to freezing over.

Shock and Vibration

In areas with heavy vibration (such as near industrial machinery), components inside the computer can collide with each other or get shaken loose of their mountings, leading to the computer failing. Impacts are another constant concern; no matter the industry, there’s always the risk of an employee dropping their equipment or hitting something with it.

The Solution

To protect an industrial tablet or computer’s internal components, they will typically be soldered directly onto the board rather than use sockets or grid arrays. This type of connection is more time-consuming to manufacture but far more secure. Externally, the tablet or computer’s case will be designed to absorb energy from vibrations or impacts and implement aluminum stiffeners to keep components from flexing or breaking. These cases will be tested to MIL-STD-810G parameters to ensure they can endure the worst the industrial sector can throw at them.

Lastly, if the tablet or computer comes with a display screen, it will be chemically strengthened to prevent scratches and cracks.

Dust and Debris

As anyone who has worked on a factory or machine shop floor can tell you, dust and debris can get everywhere. Unfortunately, it can also get inside a consumer-grade computer and play merry hell with its internals. Once inside, dust can clog fans and lead to overheating or settle on the circuits and cause an electrical short.

The Solution

Once again, sealed cases and fanless cooling protect the computer from outside intrusion. In particular, look for devices with an ingress protection rating of IP65. Computers and tablets with this rating are guaranteed to be protected against both dust and water jets, ensuring they keep contaminants out and can safely be cleaned after work is done.

Conclusion

When it comes to industrial applications, consumer-grade computers simply aren’t designed and manufactured to an acceptable standard. Whether you’re working on a factory floor or an oil rig, you need a computer tested to military-grade standards and proven to operate even under the harshest conditions.

If your company is looking for an industrial computer or tablet solution, contact the team at Cybernet Manufacturing. Our industrial computers and tablets are designed and manufactured to military-grade standards, ensuring they’re ready for the worst you can throw at them.

Join the conversation and connect with us on this and other relevant topics – Follow us on Facebook, Twitter, and LinkedIn.

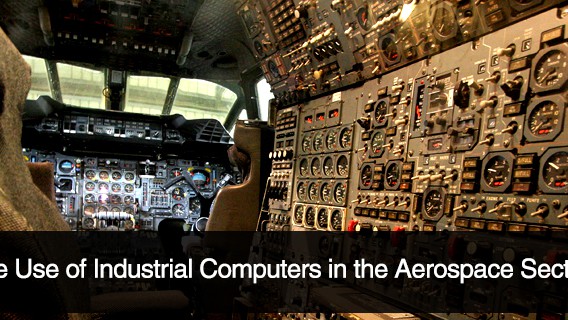

The Use of Industrial Computers in the Aerospace Sector

September 17, 2015

Over recent years, industrial computers have come to take on a critical role in a number of professions. The aerospace industry is one sector that has come to rely on the use of these devices to address a number of…

0 Comments4 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox