One of the most significant challenges for any manufacturer is satisfying the government regulations for their product or industry. Government regulations for medical devices are stringent, and for entirely justifiable reasons. Meeting these requirements is a necessary step for any product’s journey to the market.

What Regulations Govern Medical Devices?

There is a dizzying array of government regulations concerning the medical device field, but not without reason. Any device designed to sustain human life must be designed, manufactured, and tested to the highest standards possible to ensure its reliability. Otherwise, it could just as easily cause harm. The most important regulations for a device to meet are:

FDA Approval (Class I, II, and III)

The Food and Drug Administration’s Center for Devices and Radiological Health (CDRH) is responsible for regulating the manufacture, packaging, labeling, and import of medical devices sold in the United States. Under its regulatory guidelines, medical devices are divided into three classes:

- Class I: These devices are considered low risk and pose minimal, if any, risk to the patient if misused. This category includes equipment such as bandages, stethoscopes, and tongue depressors.

- Class II: Devices in this category can pose a moderate risk and require more regulatory oversight. This category includes diagnostic devices such as blood pressure cuffs and glucose meters, hearing and mobility aids, dental devices, and powered wheelchairs.

- Class III: Devices in this category are considered “high-risk” and are placed under the most strict regulatory oversight. These devices might be life-preserving or meant to operate inside the patient’s body itself, such as pacemakers, defibrillators, prosthetics, and cochlear implants.

Different classes require different levels of regulation. Most Class I devices are exempt from regulation, while Class II devices usually require Premarket Notification 510(k). This authorization demonstrates that the device is equivalent to one already on the market. As the most high-risk category, Class III requires a Premarket Approval, which often necessitates submitting clinical data to support claims made about the device.

Trade Agreements Act

For manufacturers hoping to secure government contracts, one of the most necessary steps is to ensure compliance with the Trade Agreement Act (TAA). Under the TAA, any product or device used by the U.S. government must have at least 50% of its production done within the United States.

Without this compliance, the device in question cannot be used by any part of the U.S. federal government. This is a massive market to miss out on, especially for medical device makers. The Veterans Health Administration alone is the largest healthcare system in the country, with over 1,300 facilities and a budget of $121 billion in 2024.

ENERGY STAR

ENERGY STAR is a government-implemented rating system that judges electronic devices on their energy efficiency. As a joint operation between the Department of Energy and the Environmental Protection Agency, ENERGY STAR is meant to guide consumers and businesses in finding environmentally friendly products. Any electronic device, in general, will want to get a strong ENERGY STAR rating. If you want your device to be considered for government use in particular, you should aim for at least an ES8.0 rating.

How Do You Meet Government Regulations?

Obviously, every product will have a different road from prototype to public release. However, some best practices for ensuring your devices achieve compliance are universal, such as:

Understand Your Regulatory Requirements

First and foremost, you need to understand what risk level your device poses and what class the FDA will place it in. Class I devices have it easy, but Class II and Class III examples will need significantly more documentation and even clinical testing to prove their safety and reliability. One of your first steps should be to verify which category your product falls under.

Implement Quality Management Systems

To ensure the consistency required for medical device manufacturing, it’s critical to have a quality management system. An effective quality management system, as described by ISO 13485, outlines the responsibilities of various departments, proper resource allocation, and ensures conformity of the product. All of these practices are critical for achieving and maintaining regulatory compliance.

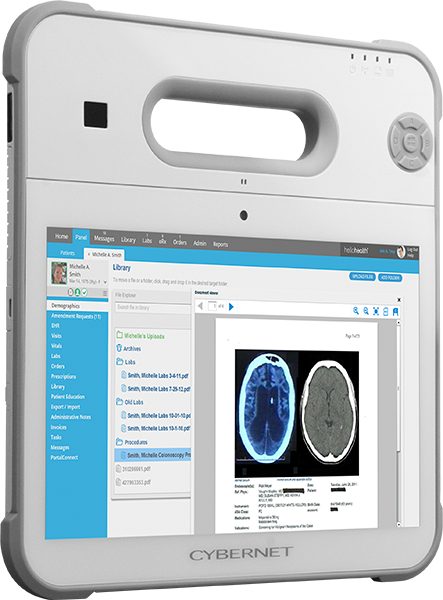

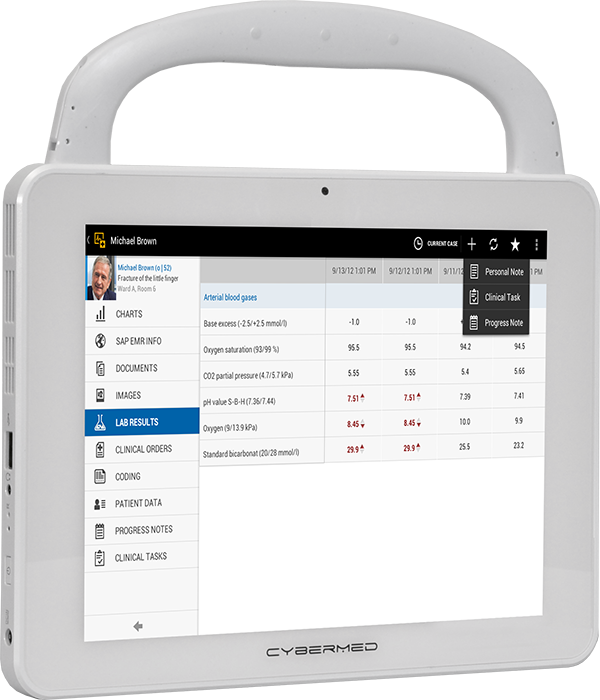

Choose Trustworthy Partners

It’s doubtful that your medical device is wholly manufactured and assembled in-house. For example, many electronic medical devices rely on an all-in-one medical PC or tablet to serve as a data collection and user interface. Selecting a PC from a trusted and certified manufacturer with its own regulatory certifications is absolutely critical. It is also essential that this partner be able to adhere to a bill of materials, as any change or deviation in their design could affect your device’s regulatory compliance.

Stay Up To Date On Regulatory Changes

Being aware of regulatory changes is critical for maintaining compliance in the future. After all, the last thing you want is for a new law to take effect and make your products illegal to sell. To prevent this, make sure you closely follow every update from regulatory bodies like the FDA or the European Union’s MDR 2017/745, so that you can be prepared for whatever changes might be coming.

Benefits of Meeting Government Regulations for Medical Devices

While it can be a long road to achieving compliance, following government regulations for medical devices is an undeniable necessity. The benefits of doing so will pay back the hassle several times over.

Regulatory Approval and Adoption

Obviously, without regulatory approval, your product cannot be legally sold on the market as a medical device. Upstanding and informed customers will have no desire to do business with you, and you will have zero chance of any government agency using your products. By achieving compliance, your company can enjoy a broader and more legitimate market for its goods.

Proven Quality

Achieving regulatory compliance with trusted government agencies is an excellent way to show the quality and consistency of your products. This sort of compliance is often a first step for private businesses and healthcare groups to consider using your devices. Any scrupulous buyer will want to know that your medical devices will keep users and patients safe.

Eco-Friendly Designs

Finding solutions that are more ecologically friendly is a hot-button topic across nearly every business sector, including medical devices. Manufacturers are increasingly looking for green computing solutions that are more energy-efficient and easier to recycle, and following regulatory requirements set by bodies like ENERGY STAR is an excellent starting point for these efforts.

Regulation-Ready Computers From Cybernet Manufacturing

Meeting government regulations for medical devices isn’t just a bureaucratic hassle, but an essential part of bringing a product to market. Achieving this regulatory compliance requires a serious commitment to quality and reliable partners for components that you have manufactured by another company.

If you need a computer manufacturer that can help you reach and maintain regulatory compliance, contact the team at Cybernet Manufacturing. Our medical-grade tablets and computers are extensively tested and certified to be ready for use in medical environments, boasting IEC 60601-1 certifications and IP65-rated front bezels for water and dust protection.