As industrial computers get more and more sophisticated in their designs and capabilities, the focus has shifted to making them more versatile and efficient. An industrial PC today, in any of its forms – fanless, panel, etc – is built to be able to cater to the requirements of any industry, medical, engineering, aviation, retail, and so on. In order to be successful in doing so, an industrial PC must fulfil certain common criteria. Chief among these are durability, heat and water resistance, shock and vibration resistance, and wireless connectivity.

3G/4G wireless functionality has had a lot to do with the popularity that industrial PCs currently enjoy. By eliminating the need to hardwire each and every computer in an industrial setup, 3G/4G has set the stage for a much more evolved approach to industrial computing, and here’s how:

Widening the Field

Article Guide

Industrial establishments are often set up in remote locations, where hard wired connections are difficult to implement. These environments include manufacturing plants such as in the automobile industry, where intelligent connectivity protocols are just as important as the physical toughness and internal configuration of each individual machine. When on the field, a high-speed wireless functionality goes a long way in removing the hassle of cables, tethering and bulky control units from the equation, relying instead on the existing cellular service in the concerned location.

M2M Communication and Automation

The high data transfer speeds offered by 3G/4G wireless technology facilitate machine to machine communications and data sharing between multiple nodes of an industrial setup. It enables live video streaming and real time monitoring, thus keeping the field units of an industrial establishment up to speed with control centers spread across multiple locations. With individual machines efficiently participating in a shared process remotely, without the need for human supervision, the groundwork for smart industrial automation is laid.

Embedded Computing Applications

3G/4G wireless capabilities allow industrial mini PCs to be used as embedded computers. These compact fanless computers, when reinforced with wireless connectivity, can cater to dedicated tasks within a large or complex mechanical or electrical system. Such embedded systems have numerous applications today; vital stats monitoring equipment and medical imaging systems (PET, CT, MRI, etc.) in the medical industry are good illustrations.

Staying up to Speed

3G/4G wireless functionality also enables industrial computers to be upgraded remotely, whether in terms of improvements to their software capabilities, or in terms of streamlining or expanding them with newly developed functions significant to the particular industry they belong to. The upgrading process becomes much simpler and more convenient thanks to a high speed wireless connection.

3G/4G wireless functionality has affected a sea of change in how industries function, and will no doubt pave the way for a future with many more possibilities. This technology has, in a sense, completed the definition of the modern industrial computer, by adding to it the capability to do its job from anywhere and everywhere, regardless of physical and/or connectivity constraints.

The Role of Industrial Computers in Industrial Automation

July 2, 2020

Industrial automation, as the name suggests, refers to using industrial computers in order to automate industrial processes. It may be understood as an umbrella term for computer automation of design, manufacturing and…

0 Comments9 Minutes

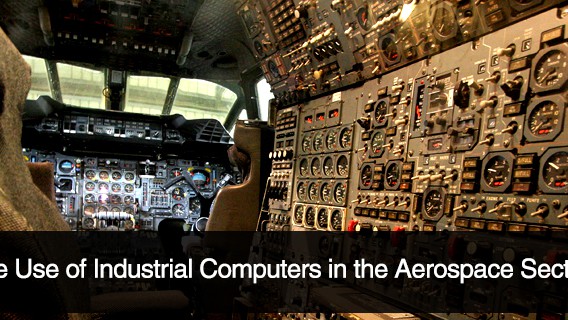

The Use of Industrial Computers in the Aerospace Sector

September 17, 2015

Over recent years, industrial computers have come to take on a critical role in a number of professions. The aerospace industry is one sector that has come to rely on the use of these devices to address a number of…

0 Comments4 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox