The first industrial robot, the Unimate, made its debut in 1962. First used in a General Motors plant, the robotic arm was quickly adopted by other automakers, then entire industries. We cover today what makes up an industrial robot, the different kinds, and – most importantly – what they do that make them indispensable in today’s modern world.

What is an Industrial Robot

Article Guide

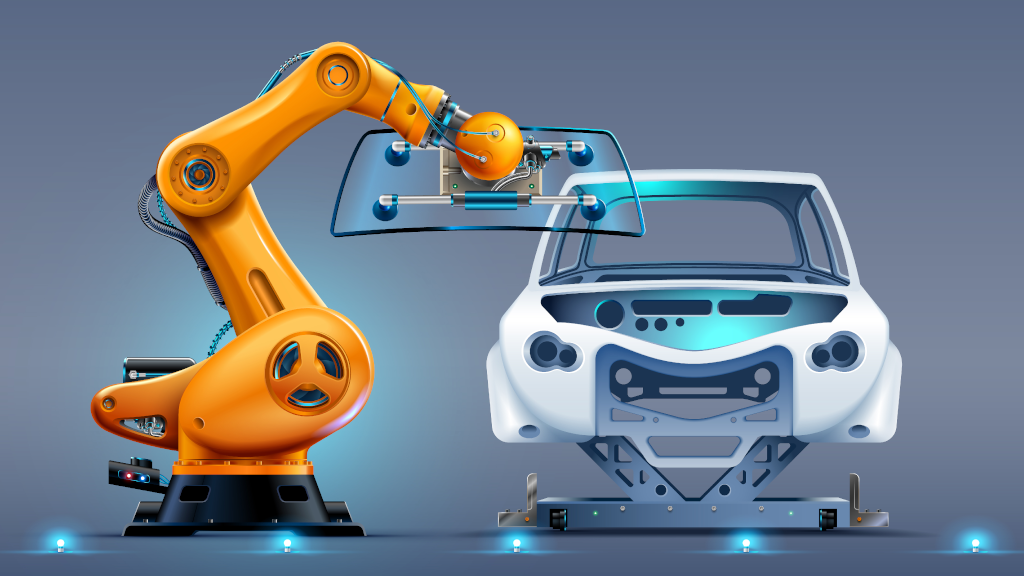

An industrial robot is a machine used for manufacturing. It is programmed to perform production related tasks automatically. Unlike what’s portrayed on television and in the movies, industrial robots don’t have a humanoid form. Instead, they look like a mechanical arm or arms that move about in several, programmed directions.

Industrial robots can be broken down into five main parts:

- A controller or “brain” housed within an industrial mini PC.

- Sensors like cameras.

- Robotic manipulators aka the “arm(s)”.

- The “hand” at the end of the arm called the End of Arm Tooling (EOAT).

- The drive which is an engine or motor that powers and moves the robot.

Some of the largest users of industrial robots are the aerospace, automotive, electronics, food, and medical industries. Industrial robots can also be found working in:

- Consumer goods

- E-Commerce

- Hardware

- Liquor distribution

- Manufacturing

- Quality control and inspection

- Retail

- Warehousing and distribution

Five Major Types of Industrial Robots

Industrial robots commonly break down into the following groupings:

Articulated robots – Also called robotic or manipulator arm(s). The most common industrial robot, they can be found from assembling parts on EV car manufacturing to packing eggs into egg cartons.

Cartesian industrial robot – Also called a linear robot. Movement is contained in straight lines along the X-Y plane and at right-angles with each other. This makes them useful in industries involving precision milling, plotters, CNC machines, and 3-D printing.

Collaborative industrial robots – Known affectionately as “cobots”, these industrial robots are designed to closely work with humans. Because of the possibility of injury, collaborative robots come with advanced safety sensors and collision avoidance technologies. This allows them to detect when there is an intrusion (especially human!) in their work area. The cobot can then either slow its tasks, pause, or even stop entirely depending on how close the intrusion may be.

Delta robots – Nicknamed “spider robots,” these machines consist of a core body with several attached light-weight arms that resemble spider limbs (hence the name). Delta robots are used for quick pick-and-place tasks like those found in the medical, pharmaceutical, and – especially – in the packaging industries.

Selective Compliance Assembly Robot Arm (SCARA) – These industrial robots main features are two horizontal joints designed to operate on a single plane. Arm movement is confined primarily to extending and retracting (folding). This design makes them well suited in high-speed pick-and-place and assembly tasks found in the electronics and automotive industries.

What Can Industrial Robots Do That Humans Can’t?

Companies use industrial robots to carry out many different types of tasks in a variety of environments. Usually the tasks and/or environment are either dangerous to human workers or require levels of consistent accuracy, speed, and repetitiveness that a flesh-and-blood being simply cannot match.

Examples:

- High-pressure rooms or vacuum chambers.

- Certain clean rooms where even the slightest contamination can be costly.

- Areas where there are possibilities of threats such as explosions, infections, radiation, and other similar hazards.

Industrial robot arms can move in several directions. The manipulators can be equipped with any type of tool and be programmed to use them. The variety of applications this allows include:

- Cutting: Slash precise paths into materials through dangerous means like laser, plasma, and water jet cutters.

- Finishing: Grind, trim, fettle, polish, and clean products to a consistent quality and finish.

- Handling: Pick and place items as diverse as heavy crates to delicate eggs from the conveyor line to packaging.

- Palletizing: Load corrugated cartons or other packaged items onto (or off!) a pallet in a specific, programmed manner.

- Seal and gluing: Apply a sealant or glue accurately and consistently.

- Spraying: Spray volatile and hazardous applications like solvent-based paints and coats onto product surfaces.

In 2020, the industrial robotics market reached 37,876.0 USD million worldwide. Compound annual growth rate (CAGR) between 2021 to 2030 is to average 11.7 percent. By the end of the projected time period, market value is expected to reach 116,848.7 USD million.

Closing Comment

Industrial robots are robot systems primarily used in manufacturing for tasks not suitable for human workers due to extreme difficulty or hazardous environments. The five major types can be found performing a variety of tasks depending on their programming.

Contact an expert at Cybernet if your company uses industrial robots and is looking to find the right industrial PC or tablet to control or program them.

Join the conversation and connect with us on this and other relevant topics – Follow us Facebook, Twitter, and Linkedin.

The Role of Industrial Computers in Industrial Automation

July 2, 2020

Industrial automation, as the name suggests, refers to using industrial computers in order to automate industrial processes. It may be understood as an umbrella term for computer automation of design, manufacturing and…

0 Comments9 Minutes

The Use of Industrial Computers in the Automotive Industry

August 20, 2019

The automotive industry invented automation: it’s no surprise that they’ve embraced industrial computers faster than any other field of manufacturing. Because automotive manufacturing requires flexible solutions that…

0 Comments7 Minutes

Collaborative Robots in Manufacturing and How to Dip Your Toe into Automation

August 25, 2020

For all the huffing and puffing about how important industrial automation is, it can be rather hard for smaller plants to break into when you consider all of the moving parts needed- IoT devices, tailored industrial…

0 Comments10 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox