The ongoing march of technology inevitably means that new tools become available and old ones get discarded. Even a sector as resistant to change as healthcare must inevitably upgrade its equipment over time. Knowing when and how to replace or upgrade aging medical technology is a critical skill for healthcare groups.

Reasons to Upgrade or Replace Medical Technology

But why should a healthcare group try to upgrade or replace equipment in the first place? The reasons can be as varied as the conditions that healthcare providers must treat. In general, however, there are three main reasons.

Safety Concerns

Obviously, any flaw in medical tools that puts patients at risk is intolerable. This might take the form of a manufacturing defect or design error, but regardless of its nature, it cannot be accepted and must be corrected or replaced as soon as possible. Devices that lack IEC 60601-1 certification, for example, could shock a patient or affect other devices, putting the patient's life at risk. A device might also be reaching the end of its operational lifespan and be unsafe to continue operating.

In modern healthcare operations, safety concerns are also often rooted in cybersecurity issues. Older legacy equipment often lacks essential security features, such as data encryption and access controls, making it much more vulnerable to external threats. Given that a data breach can lead to an interruption of services just as dangerous as a machine breaking down

Reliability or Compatibility Issues

Medical settings are not kind to electronic equipment. Many roles, such as bedside monitoring or device control, require 24/7 uptime, which is extremely taxing on electronics. Any equipment used in healthcare must also be regularly cleaned and disinfected to prevent the spread of disease, which can easily damage or disable electronic devices without ingress protection. If a consumer-grade device cannot handle these working conditions, consider upgrading to a medical computer solution.

Compatibility is another major issue for medical technology, in terms of both hardware and software. On the hardware side of things, one common problem is I/O ports and plugs not matching. For example, an older piece of equipment might rely on serial plugs to relay information, while the more modern computer it’s meant to interact with only has USB ports. For software, this often takes the form of devices programmed to interact with older operating systems that have been phased out of service. When a healthcare group upgrades to a new EMR system, they often find that the EMR cannot gather data from their older legacy devices.

Taking Advantage of New Tools

Sometimes upgrading or replacing aging technology is a necessary part of taking advantage of other new equipment. Consider medical imaging: we’ve gone from relatively crude 2D X-ray images to 3D-rendered graphics based on MRI and CT scans that give healthcare providers 360-degree visibility into a patient’s injuries or the future surgical site. These advances let surgeons operate with greater accuracy, ensuring a faster and more comfortable recovery for the patient. However, these advanced 3D graphics require a computer capable of rendering them.

When Should You Upgrade, and When Should You Replace Medical Technology Entirely?

Now that you’ve identified your needs, the next step is to determine how to address them. Specifically, is the issue one you can overcome by upgrading your existing solutions, or does it require a complete replacement?

While every situation will be different, upgrading medical technology is often the preferred solution when the change is relatively minor. For example, suppose a medical computer cannot run EMR software effectively due to insufficient processing power. In that case, you don’t need to replace the entire computer: simply upgrading the CPU or RAM should suffice. This means that healthcare providers can continue using the tools that they’re already familiar with, rather than having to learn an entirely new set of workflows. Upgrading also has the advantage of being much cheaper than purchasing a complete replacement.

Replacing old devices is a more expensive and drastic measure, and is therefore only done sparingly. Healthcare groups want to get the maximum use out of their equipment, and constantly replacing it will quickly burn a massive hole in the budget. Outright replacement of equipment is usually done only when advances in technology require it, when the equipment in question has become too old, or when a glaring safety or security issue must be addressed.

Steps for How To Replace Or Upgrade Medical Technology

Embracing new technology is never a simple affair, especially in a field as complicated and highly regulated as healthcare. Before you even consider making a purchase, make sure you have plans for the following steps:

Consult with Experts and End-Users

Obviously, if you plan to upgrade or replace pre-existing medical technology, it’s to address an issue or correct an error with your current solutions. Talk to your end users about the issue they’re facing and how it affects their work; this feedback will help shape your efforts going forward and ensure you actually address the issue. After all, the last thing you’d want is to spend time and money on replacing old technology with new solutions only for those solutions to not actually address your problems.

Once you’ve pinpointed exactly what you need to correct, you can start consulting experts on how to address it. One of the best choices you can make during this stage is to work with an original equipment manufacturer (OEM). As OEMs have complete control over their manufacturing process, they can customize products to fit the specific needs of your role, such as including a sealed and watertight casing or integrating specific cybersecurity features.

Ensure Compatibility with Pre-Existing Tech and Workflows

Another critical step in the replacement or upgrading process is to assess how the technology fits into your overall tech stack. Ask yourself, what other hardware and software will the new equipment need to work with? Once you have the answer, make sure any potential choice can interface with other critical equipment.

For example, many medical devices, including vital life-sustaining machinery, rely on legacy I/O ports to send and receive information from computers. These legacy ports are still functional but are widely considered outdated, and most modern computers will not feature them. Any medical computer that you intend to use alongside these devices must have corresponding legacy ports to do so.

Test at a Small Scale First

Once you’ve found what might be a viable solution, don’t completely commit to it. Technology can sometimes interact in odd or unpredictable ways, and the last thing you want is to order a whole fleet of replacements only to discover an issue that renders them useless. Instead, use one or a small number of test models first to see if any unforeseen complications arise. This lets you go back and address any issues before they affect your entire workforce.

Learn How To Upgrade or Replace Medical Technology With Cybernet Manufacturing

While choosing to replace or upgrade medical equipment is never easy, it is often necessary. Whether you’re trying to take advantage of next-generation tools or address a serious safety issue, you can make the process easier with the right partner.

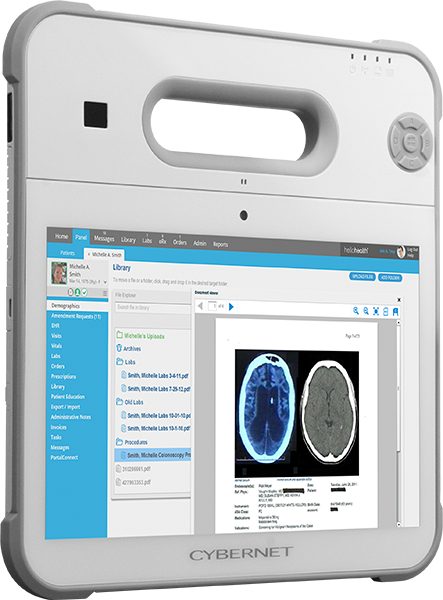

If you’re looking to upgrade or replace your old medical devices, contact Cybernet Manufacturing. Our range of medical computers and tablets is perfect for a wide range of roles, including IV compounding, charting, and anesthesia machine control, and they come equipped with a suite of features that enable them to work with both modern and legacy devices.