While the upheaval caused by COVID-19 has understandably dominated global attention for the past year and a half, it has distracted from another long-simmering crisis: climate change. The pandemic will subside, but our impact on the environment will remain. It’s easy to pay lip service to sustainability, but the reality is that it will take massive global effort across the personal, commercial, industrial, and governmental spheres of life to curb the worst effects of the impending climate crisis.

Though many in the business sector are already working towards sustainability, others may still be at a loss regarding where to even begin making their operations more environmentally friendly and sustainable. Fortunately, with the right plan and technology – like Industrial Pannel PCs and Rugged Industrial tablets – you can significantly increase the environmental sustainability of any business.

Future Climate Outlook

Article Guide

We don’t want to sugar coat it – things are bleak. Global average temperatures have already risen 1°C since reliable records began in the late 1800s. The past six years have been the six warmest on record, and 2020 was one of the top 3. 2021 is poised to continue the trend – each month so far this year has broken that month’s record. Scientists predict that if things continue as they are, we could see global average temperatures increase by up to 5°C by the end of the century. Needless to say, this would be catastrophic for both the environment and society.

But bleak does not mean hopeless. Sustainability is achievable. There are things we can do right now to prevent an absolute worst-case scenario. It will, however, take a herculean effort on everyone’s part. The UN predicts that we will need to decrease global greenhouse emissions by 7.8% PER YEAR over the next decade to limit the global average temperature increase to 1.5 degrees celsius.

Despite how dire the situation is, some people in the business world are still waiting for the state to direct them to take action. We are here today to tell you you don’t need to wait. You can and should initiate a sustainability program for your business on your own without direction from any government.

How Technology Can Reduce Your Carbon Footprint

It’s easy to trick yourself into thinking that the profit motive, the need for businesses to create and maintain steady or increasing growth, and environmental sustainability are incompatible. After all, growth takes environmental resources and energy, and how can you be sustainable if you need to extract evermore environmental resources and energy constantly?

One might think the solution is to abandon traditional notions of economic growth. However, we believe instead the answer lies in using technology to maximize efficiency. By thinking creatively and strategically deploying certain technologies, your business can thrive and grow while mitigating and even contracting its environmental impact and carbon footprint.

Below are some tips on how to use the latest in digital technology to streamline your business’s environmental impact and increase its sustainability:

Sustainability and Industry 4.0

Most blogs would focus on adopting solar energy, local energy storage, and other similar solutions as the main ways you can drastically cut your business’s carbon footprint. While we do not want to knock the already proven potential of such technologies, focusing on them too much would obscure two critical things: One, a business’s carbon footprint extends beyond electricity usage at individual facilities. Two, many smaller companies cannot justify investing in the kind of self-contained energy system that many alternative energy sources often require.

Instead, we will focus on ways you can maximize efficiency and reduce your overall energy needs regardless of their source. That way, you can reduce your carbon footprint even if you still get power from municipal coal power or other fossil fuel-based sources. These methods will also reduce the energy load on whatever solar or other alternative energy systems you install, increasing their feasibility and reducing their cost.

We’ve discussed Industry 4.0 at length before but to recap: Industry 4.0 refers to the use of digital technology like smart sensors, big data analysis, and edge computing to reduce the costs and maximize the productivity of industrial operations. While many discussions of Industry 4.0 emphasize the savings that digital optimization can yield, the same technology can be leveraged to minimize your carbon footprint while simultaneously increasing productivity.

Digital Sensors and Self Optimization

A smart factory, or a factory that has been fully upgraded with industry 4.0 technology, utilizes digital sensors deployed across their factory floor to gather data and self-optimize the operation in real-time. Typically, this is used for things like predictive maintenance – figuring out when a machine needs to be fixed before problems occur – or to prevent production bottlenecks. However, the same technology that can maximize your production output can also be used to maximize your energy efficiency.

Placing these sensors in control of machines based on their energy usage rather than just their functionality is one way Industry 4.0 can be leveraged to minimize your carbon footprint. Sensors relay data to an Industrial PC that determines which machines are drawing excess power compared to their output. The system can then use that data to restrict the ability of those machines/turn them off. Alternatively, the factory owner can use the data to decide which devices to replace with more energy-efficient ones.

More Than Just Air Conditioning

Automated climate control is another area where Industry 4.0 tech can help your business lower its carbon footprint. For example, digital temperature sensors can be placed around a factory, warehouse, or even an office building. Those sensors relay temperature data to either an enterprise computer or an industrial pc which then uses it to engage a climate control system to raise or lower the temperature in that part of the facility.

But how is that different from programing a standard thermostat? Well, for one, a typical thermostat can control the temperature in a single building, or in some cases, the floor of a building. An industry 4.0 based climate control system, on the other hand, would be more granular and provide climate control on a room-to-room basis.

It is important to note that “climate control on a room-to-room basis” doesn’t just mean “computerized thermostats direct AC in each room.” This is because air conditioning itself takes a lot of electricity to run and can have a large carbon footprint if it comes from municipal sources that utilize coal power plants. With a smart climate control system, temperature sensors send data to an Industrial PC that can direct automated processes like lowering shades over windows, dimming lights, and turning on traditional fans, all of which require significantly less energy than AC.

Supply Chain Management

Even if you’ve successfully utilized Industry 4.0 tech to maximize your operation’s energy efficiency, the truth is your share your carbon footprint with the rest of your supply chain. At its fullest potential, Industry 4.0 allows you to integrate sensor data from across the entire supply chain, from the supplier, to the factory floor, to logistics, even if a separate company handles each segment of the chain. This data helps each part of the chain communicate with each other so the entire chain can self-optimize.

You can use this data to judge the energy efficiency of your supply chain partners. If they aren’t up to your standards, you can then pressure them to upgrade their operations lest you find a more suitable partner. After all, it is often the case that shipping requires more carbon output than fabrication. Therefore, you can’t claim your products are genuinely low-carbon-footprint if it takes standard levels of carbon to extract your materials and ship your products to market.

Final Thoughts

Climate change is here and it is incumbent on all of us to act quickly in order to stave off its worst effects. It will require massive effort across all sectors, public and private, to accomplish the UN’s aggressive climate goals, but it is not impossible. Contact the experts at Cybernet today to see how Industrial PCs and Rugged Industrial Tablets can fit into a green industry solution.

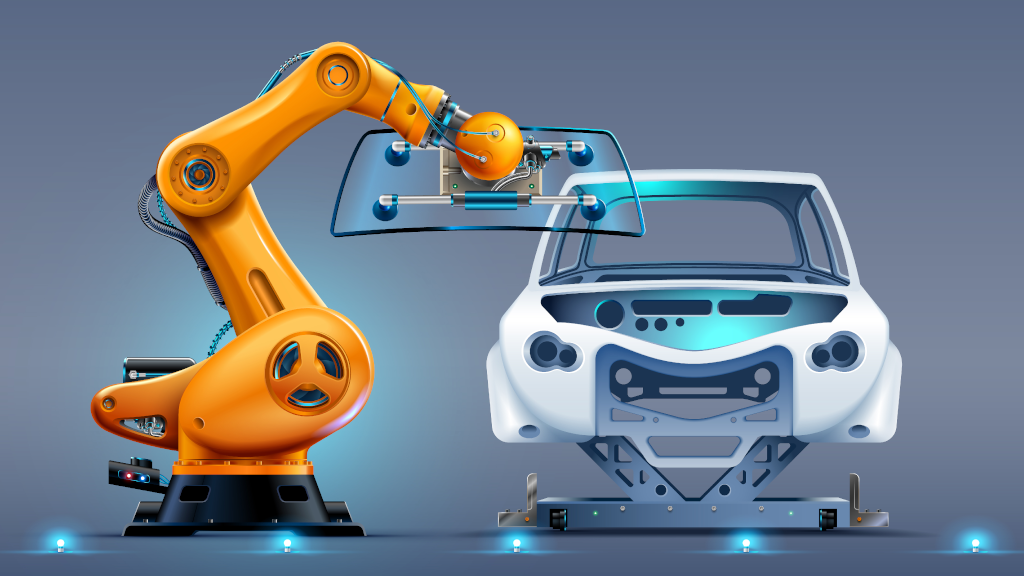

The Use of Industrial Computers in the Automotive Industry

August 20, 2019

The automotive industry invented automation: it’s no surprise that they’ve embraced industrial computers faster than any other field of manufacturing. Because automotive manufacturing requires flexible solutions that…

0 Comments7 Minutes

The Role of Industrial Computers in Industrial Automation

July 2, 2020

Industrial automation, as the name suggests, refers to using industrial computers in order to automate industrial processes. It may be understood as an umbrella term for computer automation of design, manufacturing and…

0 Comments9 Minutes

You Can't

Learn from a Pop-up

But we can deliver knowledge to your inbox!

We dive deep in the industry looking for new trends, technology, news, and updates. We're happy to share them with you.

Knowledge, News, and Industry Updates Right in Your Inbox