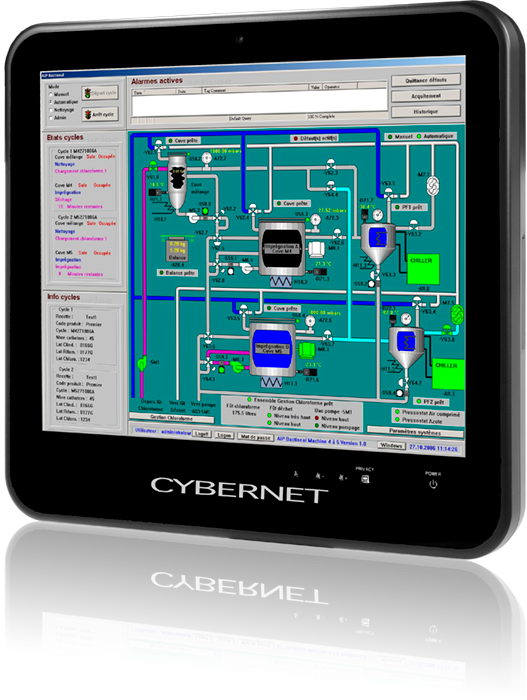

Industrial HMI Panel iPC S19

Gain intuitive, real-time control over industrial systems with the iPC S19 industrial HMI panel, built to support reliable machine interaction in demanding environments. Designed for long-term deployment on factory floors and equipment enclosures, the iPC S19 delivers consistent performance alongside other industrial computers used for automation and control. Its rugged construction and responsive touchscreen make it well-suited for a wide range of industrial use cases where durability, visibility, and ease of integration are essential.

Key Features:- Industrial Durability: Built with industrial-grade components designed to withstand temperature variation and vibration.

- Seamless Performance: Intel processors paired with up to 32GB of RAM deliver responsive computing for HMI applications.

- Versatile Use: Suitable for machine control, production environments, and warehouse automation.